Stone Crusher Manufacturers

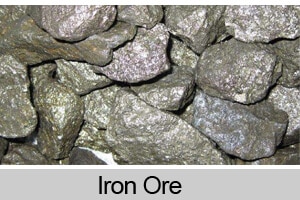

Stone Crusher Manufacturers for sand, quarry, mining, and construction. JXSC mine machinery factory set up in 1985 which has three series machines. The crushing machine, sand making machine and mineral processing equipment. The types of stone crushers are cone crusher, jaw crusher, impact crusher, and mobile rock crushing. We supply cost-effective products and first-class service, solutions, support for customers. Our factory has an area of 10000 square meters, USD 1000 million fixed assets, and the engineer and technical personnel covering 15% of the total staff. To build a factory for the production and export of China's top mining machinery is our goal.

Types of Crushers

According to the working principle of crushing classification, the crushers can be classified pressure crusher and impact crusher.

The types of pressure crushers include jaw crusher, roller crusher, and gyratory crusher. The pressure type crusher uses two hard parts of the machine to press each other to crush rock material. For example, the jaw crushers use the fixed jaw plant and movable jaw plate.

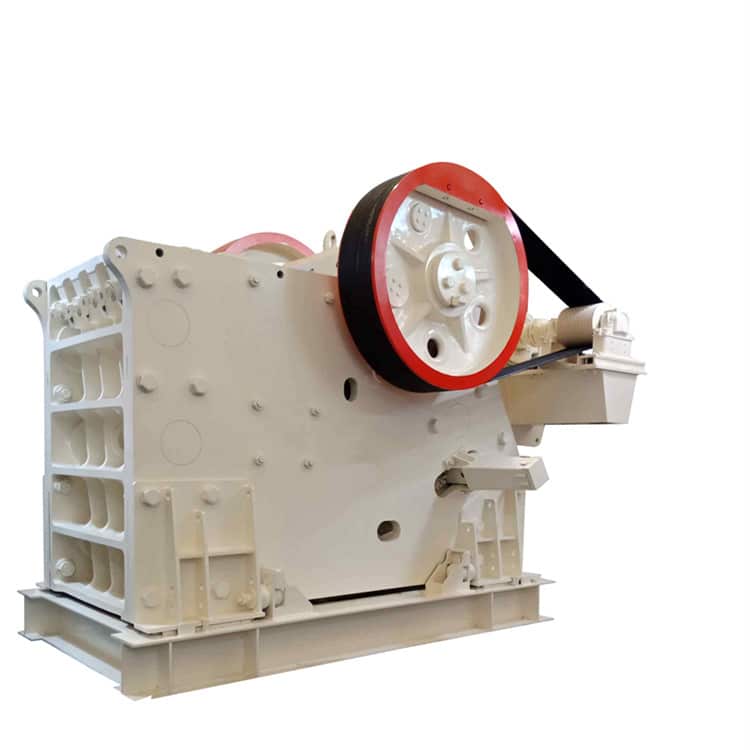

Jaw Crusher

The jaw crusher's main function is to reduce the size of the raw materials or large pieces of material to a sufficiently small size, so as to facilitate the next step of the crushed material. In the quarries and mine materials crushing plant, it is generally used as a primary crusher. The types of jaw crushers are single toggle and double toggle. The construction of the single toggle jaw crusher is compact and simple, and the transmission components such as eccentric shafts are less stressed. Due to the vertical displacement of the movable jaw is small, the material is less excessively broken during processing. Therefore, the wear of the movable jaw plate is less.

Compared with the simple pendulum type, the double toggle type jaw crusher has the advantages of lighter weight, fewer components, a more compact structure and uniform crushing, high productivity. 20-30% higher productivity than a simple swing jaw crusher of the same specification.

Roller Crusher

Tooth Roller crusher is a new product that is designed and developed according to the structure principle of Gunlock crusher in America. The machine has the advantages of small volume, high crushing ratio (5-8) , low noise, simple structure, convenient maintenance, high productivity, even particle size of crushed materials, low over crushing rate, convenient maintenance, etc. The mall roller crusher is widely used in the mining industry as a secondary crusher.

Gyratory Crusher

Gyratory crusher is a new type of crusher that can replace fine jaw crusher and cone crusher. It consists of a concave surface and a conical head, both of which are usually lined with manganese steel. The inner cone has a slight circular movement but doesn't rotate. The gyratory has the advantages of good finely crushing effect, large processing capacity, small vibration, simple maintenance, low cost, and less lining plate wear.

Impact type crusher contains hammer crusher, impact crusher, cone crusher, and sand crusher. The types of crushers via high-speed impact force to crush materials.

Impact Crusher

Impact crushers crush materials by impact rather than by pressure. The material is broken in the crushing chamber under the impact force. It can handle materials with side length less than 100-500 mm, with compressive strength up to 350 MPA. It has the advantages of a large crushing ratio and cubic particles after crushing. There are two types of impact crushers: Horizontal Shaft Impact(HSI) Crushers and Vertical Shaft Impact(VSI) Crushers.

Cone Crusher

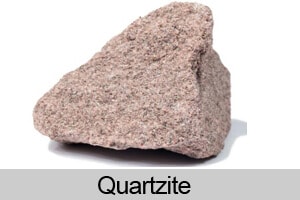

Cone crusher is suitable for crushing all kinds of medium and above medium-hard materials. It usually a secondary, tertiary, and fine crusher. The purpose is to fine crush the materials.

In the sand making plant is one of the essential crushers. Cone crusher according to the crushing force is divided into Simmons spring type and hydraulic type. Hydraulic type is divided into single-cylinder and multi-cylinder cone crusher. According to the rotary speed, there are three types: low speed, medium speed and high speed.

The basic structure of cone crusher is similar to that of rotary crusher, but the range is larger. It rotates and presses against the stone on the side of the machine, where it falls into the lower chamber and is crushed again until it falls out of the bottom. Its advantages: reliable structure, high productivity, easy adjustment, and low operation cost.

Hammer Crusher

Hammer crusher(Hammer mill) is broken by an impact between a high-speed hammer and material. This type of crusher is divided into two types: single rotor and double rotor. Single Rotor is divided into reversible and irreversible. Hammer crusher is mainly composed of the rotor, spindle, hammerhead, lining plate and impact plate. And it mainly crushing for coal, salt, chalk, gypsum, brick, limestone and so on. It also used for crushing fiber structure, flexibility, and toughness of strong broken wood, paper, etc.

The advantages of the hammer: larger crushing ratio, high production capacity, uniform products, less over-powder phenomenon, simple structure, light equipment quality, simple operation, and maintenance.

Sand Crusher

Sand crusher is also called VSI crusher. It is an indispensable equipment for artificial sand manufacturing plant. VSI crusher imported advanced German technology development and production, with the international advanced level. Its performance plays an irreplaceable role in the fine crushing equipment of various materials. There are two types of sand-making machine: stone hit stone and stone hit steel.

Stone hit stone

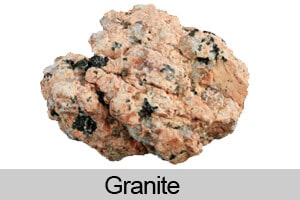

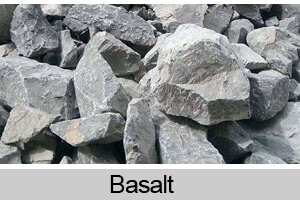

The upper and lower hitting guard plate is installed on the crushing cavity wall of the sand making machine. It makes the ore material to be crushed by the impact, friction or high-speed impact between the material and the lining layer formed by the material and the material accelerated by the flywheel when accelerating. The materials do not come into direct contact with the equipment. This method reduces the wear and tear of fittings and prolongs the service life. "Stone hit stone" sand crusher is suitable for material with high abrasion above medium hardness, such as basalt. And the finished product has good grain shape, but the powder content is a little more. So it is more suitable for aggregate shaping.

Stone hit steel

In the crushing cavity wall of the sand-making machine, the lower hitting guard plate is replaced by the perimeter guard plate. When the ore material is thrown out by the roller, it is directly impacted on the guard plate for many times and the crusher. Under the constant impact, and then the crushing cavity material impact, ore material broken more fully, and the finished material particle size smaller. The "stone hit steel" sand crusher is suitable for small abrasive materials below medium hardness, such as limestone, and the crushing efficiency is high. However, due to crushing depends on the impact, so wear parts are higher. The finished product is slightly worse, it is more suitable for sand-making.

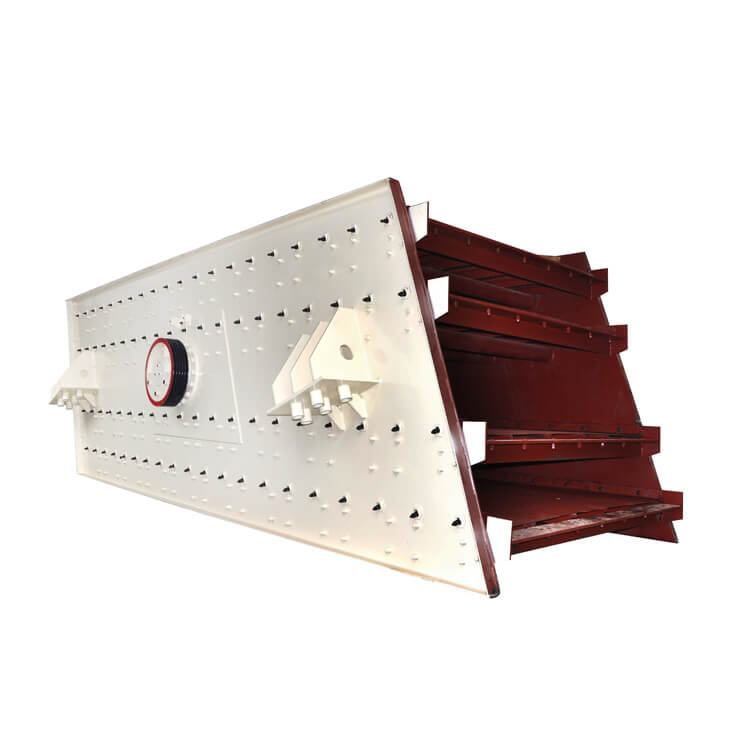

JXSC products and solutions mainly used in mining, such as jaw crusher, cone crusher. Quarries, such as sand plant, stone crusher plant. Grinding, such as rock hp cone crusher, sand making machine, sand washing machine. Construction waste recycling, such as mobile jaw crusher, mobile cone crusher. Auxiliary equipment, such as vibrating screen, vibrating feeder; spare part. JXSC is a heavy industry high-tech company that integrating R&D, production and distribution.

Why Choose Us

1. 40 years old

JXSC Mine Machinery Factory founded in 1985, and we have 40 years of production experience. In the 40 years, we are committed to the development, production, sale of high-quality crushing equipment, mining and mineral processing equipment. We have mature manufacturing technology, excellent engineers, design and manufacture high-yield crushing plant, sand plant mining plant for users.

2. The professional custom-made, all-round solution to the needs of users

We can design and customize the best applicable equipment according to the specific conditions of the mine for use.

3. Considerate pre-sale service, after-sale guaranteed service

We have a professional sales team to answer all your equipment questions. Take the customer to the factory to see the equipment and free test machine. We provide equipment installation schematic diagram, video installation guide. In some places, our engineers can go to the site to install and debug. All the equipment is guaranteed for one year, except for the wear parts.

Rock Minerial Crusher Plant

Blog Posts

Types and Advantages of Small Mobile Crushers

A small mobile stone crusher is very suitable for small and medium-sized stone crushing and processing. Traditional sand production lines require initial preparation investment, laying a foundation, and transport materials back and forth. The operating cost is not cost-effective. Unlike stationary sand production lines, mobile stone crushers operate in a …

Bentonite Processing Plant And Grinding Machine

Bentonite is a water-based clay mineral that mainly consists of montmorillonite. Bentonite is famous as the “universal” clay for its excellent physical and chemical properties. It is suitable for producing binders, suspension agents, thixotropic agents, stabilizers, purification and decolorization agents, fillers, feed, catalysts, etc. It has wide applications in metallurgy, …

How To Reduce The Stone Crusher Operating Cost?

With the technology development, mining machine manufacturers are constantly improving the performance and expanding the application range of stone crushers. The jaw crusher, impact crusher, hammer crusher, cone crusher, impact crusher, and mobile crusher are suitable for crushing various stones. They have high output, a good crushing effect, and long …

Engineer On-line

Don't hesitate to call us