HP Cone Crusher

Feeding Size: 95-350mm

Capacity: 90-1200TPH

Application Field:

Quarries, mining, aggregate processing, industries of metallurgical, chemical, construction, cement, etc.

Suitable Material:

Cobble, granite, basalt, iron, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc.

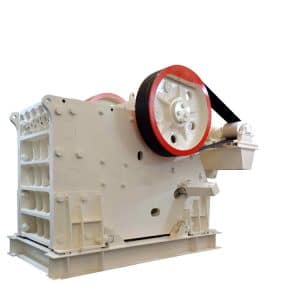

What HP Cone Crusher

JXSC HP(Hydraulic Multi-cylinder) Series Cone Crusher is developed on the spring cone crusher. It has the hydraulic adjustment function and stronger elastic recovery function, and with the more comprehensive insurance measures. The types of cone crushers use advanced technology, numerical control operation. The useful life increased by 30%-50% because of the working principle of more grind less crush.

JXSC HP cone crusher has the invincible advantages in the 2nd, 3rd, 4th crushing stage for a wide range of applications including mineral processing, aggregate processing, quarry plant, etc. Bring revolutionary meaning for cone crusher development, because of its compatible function of all day working, automation, high crushing performance, low probability of choking.

Popular HP series cone crushers have HP100, HP200, HP300, HP400, HP500, HP800, well-known cone crusher manufacturers: Nordberg, Metso, Sandvik.

Only constant innovation can create greater success, and so can cone crushers. Nordberg cone crusher absorbs and develop the advantages of Symons crusher and Omnicone, and be proved that combines with the marketable performance like high capability, easy operation, low wear cost, long service life, and best product shape.

HP cone crusher main parts are feed bowl hopper, adjusting ring, mainframe, gear, eccentric, hydraulic motor, countershaft, tramp release, etc.

HP Cone Crusher Advantages

Less downtime

The hydraulic tramp release design enables the cone crushers minimizes the possibility of choking caused by the tramp iron, and the large clearing stroke further reduced the downtime thus increase the efficiency.

Long service life

The high-performance sealing system prevents dust entry into inner frame unless worn, that means to have a protection of moving parts reduce the possibility of contacting the rock and dust, and prolong the service life of the wear parts( head ball, liner, countershaft, feed hopper, etc.)

Easy to operate

The hydraulic motor setting system greatly reduced the operation difficulty by high automation performance, more accurate setting maximum the capability while optimal crushing circuit. Besides, the design of a data transducer enables the HP cone crusher connecting to the DCS control system for intelligent operation.

Versatility

HP cone crusher combines with the advantages of the Symons. only need to change the bowl liner, mantle and other components can apply in different stages which from secondary to quaternary, from coarse to extremely fine.

Multi-cylinder hydraulic cone crusher working principle

When the multi-cylinder hydraulic cone crusher works, the motor drives the transmission shaft twirl by the belt pulley and the triangle belt. The transmission shaft drives the mantle rotates around the spindle through the big and small bevel gears. The eccentric sleeve drives the movable cone rotation. The movable cone and fixed cone sometimes near and sometimes far from the wall of the rolling mortar, the materials in the crushing cavity are constantly ground and crushed, then the crushed materials are discharged from the lower part.

When there is a non-crushed material(such as iron) in the crushing cavity, the hydraulic overload protection system with automatic reset. The upper frame lifts up, the iron and another un-crushable permit to pass. Then the system automatically returns the upper frame to its original position.

How to choose a cone crusher?

Cone crusher is an important part of crushing circuit which including rock crusher, material feeder, vibrating screen, convey belt. The determination of cone crusher is very key to the performance of the crushing plant. As the following factors will improve crushing capability and efficiency should be taken into consideration.

1. Selecting the suited crushing chamber

2. proper particle size proportion of feeding material

3. Adjustable feed port and feed speed

4. Ores distribute uniformly in the crushing chamber

5. Automation system

6. Enough space for discharging

What should be avoided?

1. Bad fluidity and sticky feed material

2. High content of moisture

3. The particle size proportion of extremely fine is 10% higher than that of the crusher setting.

4. Uncontrolled feed rate.

5. Extremely hard rock with high crushing difficulty

6. The crusher operates at a slower speed than the recommended full load countershaft.

Detailed solutions, consult JXSC engineer team.

GET MORE INFO