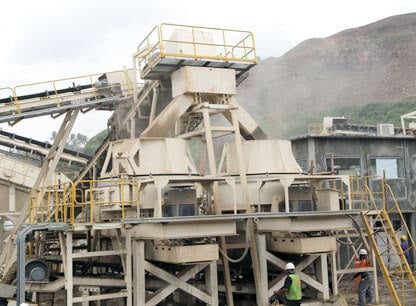

Sand Plant

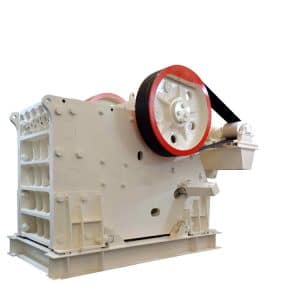

The sand plant produces artificial sand and industrial sand which replace the river sand. In this plant, it can divide into the sand making plant and sand washing plant. JXSC manufactured sand equipment manufacturers offers crushing and screening equipment, such as VSI crushers, jaw, impact, cone, hammer crusher, vibrating screen, and sand making & washing machine. Stone crusher equipment is mainly to the primary crusher, and the sand making equipment is mainly to fine crushing.

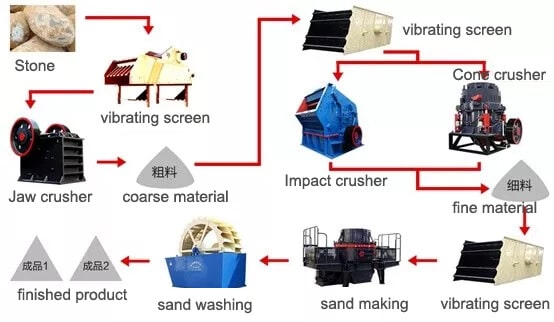

Sand Making Process Plant

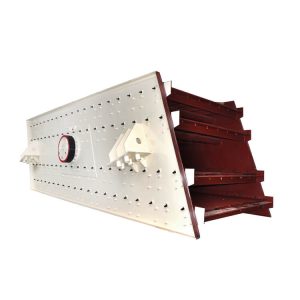

Rock materials are fed into the jaw crusher by vibrating feeder, then crushing by cone crusher, impact crusher, sand making machine. The crushed rock that reaches the standard after screened by a vibrating screen is transported to a sand washer, Last, the final product is completed. Another side, not up to the standard of materials carry back sand making equipment to the machine. The recovery line is accomplished. Each piece of equipment to link together is use belt conveyor. All the quarry, aggregate, limestone, iron ore, pebble, granite, basalt belongs to rock materials.

Artificial sand can be used to the building materials, highway, railway, concrete mixing plants.

Customer feedback: The Sand Production Line is very flexible in adjustment, high production capacity, automation operation and easy in maintenance. In addition, the service cycle of accessories is long, the maintenance rate is low, the maintenance is convenient, the production time is saved and the production cost is effectively reduced.

JXSC Machinery sand making production line was based on the actual needs of customers, adjust the structure of the production line, to produce a variety of high-quality crushed stone aggregate. With the professional design concept and reasonable production configuration, the “three high” coefficient is realized: High Production and quality coefficient, high automation coefficient,

Raw Material: mountain stone

Capacity: 12.5T/H

Feeder Size: 150-230mm

Output Size: Standard sand size for gypsum which uses in concrete construction and bricklaying.

Raw Material: stone

Capacity: 150TPH

Customer mine Country: Philippines

Output size: 0-3mm, 3-6mm

The ways of artificial sand making processing

Artificial sand can be produced in two ways, dry sand making, and wet sand making.

What is dry sand making

Dry sand-making is not to use water to remove the mud powder in the artificial sand, but through the powder, concentrator to remove the mud powder. To reduce the content of mud powder in artificial sand, so as to get better sand, guarantee the quality and taste of manufactured sand. This method of sand production is suitable for areas far away from water sources, such as arid areas.

Dry sand making process

The raw material is fed through a vibrating feeder, on the one hand sieving small pieces of weathered stone and soil, on the other hand feeding large pieces of stone into coarse crushing equipment. After coarse crushing, it enters the medium crushing equipment and then passes through the vibration to feed the screening. Recycle Processing of crushing equipment in return of a large stone. According to the actual needs, a part of a 40-80mm block finished aggregate can be produced. The stone which meets the requirement of feeding size of vertical impact sander enters the sander to be broken and shaped. After examination and screening, it is divided into the sand and small aggregate in various finished products.

According to the need, the screening equipment can be divided into a variety of finished aggregate proportions. Part of the return to the sand making machine cycle crushing. Finally, high-quality artificial sand is obtained by using a powder separator. Adopts high-efficiency dust remover dust, low cost, and solves the problem of dust pollution in dry process sand making plant and the content of sandstone powder exceeding the standard. The recovered stone powder can be used to make bricks, etc.

Advantage:

1. Dry Sand production process reduces the use of water resources costs, and not subject to regional environmental constraints.

2. The sand plant layout compact, small footprint.

Disadvantage:

1. Dust content is large, easy to cause air pollution.

2. The requirement of raw materials is high, and the content of impurities such as soil and organic matter in sand and stone should be strictly controlled.

What is wet sand making

Wet sand making is a sand making process + sand washing process. Rounded to the appearance of sand grains and reduced soil content, this process is suitable for water-rich areas, close to water sources. It can establish a sedimentation tank to achieve water recycling, but also can add the fine sand recovery machine to collect the fine sand in the wastewater.

Wet sand making process

The front process of wet sand-making is the same as that of dry sand-making. except that the finished sand is washed by a spiral or wheel washing machine. The wastewater and washed sand can be recycled in the fine sand recovery unit according to the actual situation.

Advantage:

1. There is no dust pollution and reduces air pollution.

2. The sand made has a clean surface, around appearance, and a good appearance.

Disadvantage:

1. Needs a large amount of water resource in the wet sand making process, and the cost is high.

2. Limited by environmental geography, the region's water resources can not be used if not enough.

Difference between dry and wet sand making

1. Behind equipment is different

Wet sand-making is the mode of the sand washing machine, which can reduce the soil content of machine-made sand, the appearance of sand is round and the quality is beautiful. Dry Sand making is a mode of using powder separator, which can realize the separation of sand and powder. Select high-quality sand suitable for building sand.

2. Investment cost is different

A large amount of water is used to clean the sand in the wet sand production process. Dry sand-making is separated by powder separator and does not need to use a lot of water.

3. Areas different

Wet sand making plant is suitable for areas with rich water resources and close to the water source. And can also establish a sedimentation tank, water resources to achieve recycling. The dry sand-making process is not limited by the environment, and it can also be realized in areas where water resources are scarce.