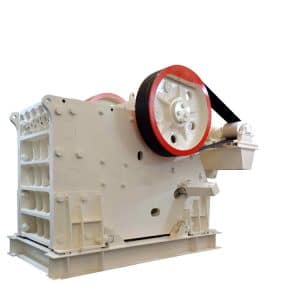

Compound Cone Crusher

JXSC Compound cone crusher is improved modified by Symons cone crusher, which is the high-performance cone crusher that introducing advanced foreign technology. The crusher equipment has product characteristics of superior quality and reliable performance. The crusher equipment adopts the best combination of crushing frequency and eccentric distance, which makes the crushed materials have a higher crushing degree. The crushing productivity is higher than other crushers. The crushing equipment's operation becomes more automatic because it uses the devices of hydraulic safety, hydraulic lock, hydraulic adjustment, hydraulic cavity cleaning, etc. Compound cone crushers are widely used in sand plant and crusher plant as secondary or tertiary crusher machine. Feeding size: 80-300mm. Capacity: 60-610tph.

Application Field:

Quarry, mining, coal mining, dry powder mortar, concrete mixing station, power plant desulfurization, quartz sand, etc.

Suitable Material:

Pebble, granite,basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Compound Cone Crusher Benefit

Advantages:

1. High reliability and good stability. With large diameter spindle, heavy mainframe and independent of the dilute oil lubrication automatic control system which ensures the equipment is durable reliable operation. Hard protection device can ensure the impurities through the crushing chamber. Then the machine rapid restoration of normal operation.

2. Repair is convenient and easy to operate. All the parts are capable of dismounting from the upper or side. It uses a sliding bearing, compared with the rolling bearing. It not only has the bearing performance better but also more economical, more convenient repair.

3. Low cost and a wide range of applications. Large capacity, high reliability, convenient repair, low operation cost. It can be used for material high hardness materials and low hardness of coarse crushing and fine crushing work.

4. High crushing ratio, high efficiency, and energy-saving, crushing cavity, cavity cleaning convenient, stable performance, firm structure, convenient maintenance, low cost, good sealing performance, little flakiness content.

Working Principle

When the composite cone crusher working, the motor drives the eccentric sleeve to rotate via the belt, a big belt wheel, transmission shaft, bevel gear, bevel gear. Crushing cone axis swinging under the force of the eccentric sleeve, the surface of the broken wall sometimes close to and sometimes leave the rolling mortar wall surface. Material impact, extrusion, bending and crushing, in a ring crushing cavity of the fixed cone and moving cone. After repeated extrusion, impact and bending, material crushing to the required size, discharge from the outlet.

What is a Symons cone crusher

The first cone crusher in the world is invented by Milwaukee Symons brothers in the 1920s. Symons cone crusher was named because of Symons brothers' names. Although it was not important news at that time, It has made a great contribution to the improvement of the later crushing equipment. If there wasn't the Symons cone crusher, there wouldn't the hydraulic cone crusher.

Because the cone crusher is widely used in rock crushing, people have been exploring and researching. At the end of the 19th century, the spring cone crusher became one of the most efficient crushers.

In 1984, the first hydraulic cone crusher was developed. When the non-crushed materials(such as ore) through the crushing chamber, the series of cone crushers is through the hydraulic system to expand the crushing chamber. Therefore, the on-crushed materials pass the crushing place. The hydraulic system protects the crusher from damage. In recent years, the technology, efficiency, function, maintenance costs of the cone crusher have been outstanding improved. Symons cone crusher needs to manual operation, but the hydraulic cone crusher can be controlled by an electric control system.

GET MORE INFO