Stone crusher is mainly used for crushing operation in quarry crushing plant and mining plant. There are 5 types of stone crushers: jaw crusher, impact crusher, hammer crusher, cone crusher, and VIS crusher. What is the application of the 5

types of stone crushers and how to maintenance? This article is about a thorough introduction.

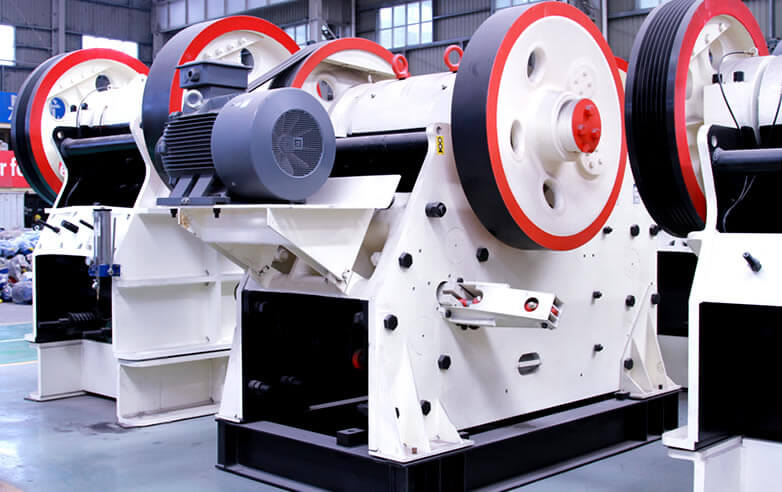

Jaw Crusher

Jaw crusher is a heavy-duty which crushing the hard rock. Therefore, the jaw crusher parts need to be very hard and durable. In particular, the two components of the jaw crusher work, the fixed jaw, and the movable jaw. The crushers machine are widely used in industries of mining, building materials, roads, railways, water conservancy, and chemical. The types of jaw stone crusher: single toggle jaw crusher and double toggle jaw crusher.

Routine Maintenance

During the maintenance of the jaw crushers, wear part is a common occurrence. This is also the main wear in the stone crushing line. Therefore, we recommend that customers purchase high-quality jaw crushers, which are more durable and have better running performance. During use, it can avoid many unnecessary wear problems and reduce the trouble of frequently changing parts. 8 notes of jaw crusher routine maintenance.

1. Check the heat of the bearing. The temperature of rolling bearings

doesn’t exceed 70 ° C. If exceeds the specified temperature, it must stop and immediately check and troubleshoot.

2. Check whether the lubrication system is normal. Whether there is a crash of a gear oil pump. Observe the value of the oil pressure gauge and check whether the lubrication system in the fuel tank leaks oil. If find the above various conditions are abnormal, dealt with they in a timely manner. The place of movable jaw suspension bearing and the elbow, it should lubricate regularly which automatic or manual oil pump lubrication.

3. Check whether the oil contains metal powder and other contaminants. If there is dirt, stop the bearing and other parts to check.

4. Check whether there are loose joints between the bolts and flywheel keys of each part.

5. Check the wear of the gear plate and transmission components, and whether the lever spring is normal.

6. Always keep the equipment clean, so that there is no dust, no oil, no oil leakage, no water leakage, no leakage, no leakage. Especially pay attention to prevent dust from entering the lubrication system and lubrication parts.

7. Clean the filter cooler regularly, and wait until it is completely dried before washing.

8. Regularly change the lubricating oil in the fuel tank. Usually once every six months.

Impact Crusher

The impact crusher crushing the soft and very hard materials, even if there is moisture in the material. The types of stone crushers are widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, chemical and other industries for medium and fine materials.

Routine Maintenance

In order to ensure the service life of the impact crusher, we should always maintain the machine.

Daily check

1. The jaw crushers run smoothly. When the vibration quantity of the machine suddenly increases, it should stop immediately to find out the cause.

2. Under normal conditions, the temperature rise of the bearing should not exceed 35℃, and the maximum temperature should not exceed 70 ℃. If it exceeds 70℃, stop immediately and find out the cause.

3. When the plate hammer wear reaches the limit mark, it should be turned around or replaced in time.

4. After assembling or replacing the hammer, it must maintain the rotor balance, and the static balance should not exceed 0.25kg.m.

5. When the rack lining wear, replace it in time which can avoid wearing the casing.

6. Check the tightening status of all bolts before starting each time.

Lubricating

1. Always pay attention to and timely lubrication of the friction surface.

2. The lubricating oil used in the impact crusher should be determined according to the location of the crusher machine, temperature, and other conditions.

Cone Crusher

Cone crusher is an advanced hydraulic crusher with high power, large crushing ratio, and high productivity. Generally, it uses as a secondary crusher to break medium-hard materials, and use as fine crushers in artificial sand making process plants and quarry plant. Cone Crusher is a hydraulic crushing machine suitable for use in raw materials in the metallurgical, construction, road construction, chemical, and silicate industries. Types of cone stone crushers: GP cone crusher namely single-cylinder hydraulic cone crusher, HP cone crusher namely multi-cylinder hydraulic cone crusher, Compound cone crusher.

Routine Maintenance

1. There must be a de-ironing device to prevent the crushing chamber from passing through the iron. If the iron is frequently over-exposed, it may cause a shaft breakage accident.

2. To be fully loaded, otherwise, the product size will be too thick.

3. The crushing ratio in the production line should be reasonable, so as to maximize the efficiency of the crusher.

4. The spring pressure should not be too tight. If the pressure is too high, the shaft breakage will occur. If the pressure is too small, the spring will jump frequently which affecting the normal operation of the crusher. The product size will become thicker.

5. The temperature of the lubricating oil should not be too high or too low. Otherwise, it will affect the operation of the machine.

6. A lubricating oil should be replaced frequently. Not too dirty. If it is too dirty, it will accelerate the wear of gears, bowl-shaped tiles, bushings, etc., and even make the bushings die.

7. The drive belt installation should not be too tight. Otherwise, it will cause the driveshaft to rotate inflexible or broken. It should not be too loose, otherwise, it will cause the crusher to suffocate.

8. The feeding material should not be too wet and too sticky, the fine particles should not be too much, and it should not be too big. Otherwise, it will cause boring.

Hammer Crusher

Hammer crusher is a high-speed rotary crushing machine. The crusher is suitable for crushing medium hardness materials in industrial sectors such as cement, chemical, electric power, and metallurgy. The medium hardness materials such as limestone, slag, coke, coal and other materials in the medium and fine crushing operations. The hammer mill rock crusher can be used not only for crushing plant, sand making plant, it also can replace cone crushers in mining plant. The types of stone hammers crushers: single-stage hammer crusher, high-efficiency hammer crusher, sand making machine, vertical shaft hammer rock crusher, reversible hammer crusher, double rotor hammer crusher, ring hammer crusher.

Routine Maintenance

1. It should contact the upper and lower procedures related to the machine before starting to stop. And perform the correct operation in the order of opening and stopping.

2. To start the empty machine and should empty the material in the crushing chamber and then stop.

3. Always check all the anchor bolts and lining bolts of the equipment for looseness. If loose, tighten them in time.

4. Check the use of easy-to-wear and easy-to-wear parts such as hammerheads and linings. If we find the problems, they should be disposed of in time.

5. Look at the lubrication and keep the lubrication system in good condition.

6. Keep the feed even and take care not to feed metal debris.

7. Pay attention to check whether the discharge granularity meets the quality requirements. If it does not meet, replace the purlin or adjust the height of the purlin bracket.

VSI Crusher

VSI crusher is a kind of sand making machine which uses in sand plant and quarry plant. The VSI sand making machine is a hydraulically impact sand making machine that is 50% more energy-efficient than conventional machines. It can make all kinds of rocks, sandstones and river pebbles with construction sand of various grain sizes. The uniformity of sand and high compressive strength.

Routine Maintenance

Firstly, the inspection of sand making equipment before starting. Check whether the machine cavity inspection door is closed. If no close, close it to prevent the material from flying out and posing a danger to the staff. And the lubricating oil of the equipment should also be inspected.

Secondly, it is necessary to check whether the power supply of the VSI series sand crusher machine is turned on normally and there is no overload.

Thirdly, the starting sequence of the VSI series crushers must be correct. It is generally installed in the following order: vibrating feeder – jaw crusher – sand making machine – vibrating screen – sand washing machine. In the event of a shutdown, you need to operate in reverse order.

Finally, it is necessary to ensure the normal feed rate and volume of the equipment during the production process. We must strictly follow the feed size required by the equipment. Forbidding to enter metal materials and large stones to prevent damage to the parts of the equipment. If we find severe vibration or loud noise during the production process, stop and inspect in time for timely treatment.