Cone crusher is crushing equipment for the industry of metallurgy, building, road, chemistry and silicate. Classification of cone crushers is HPC cone crush, cs cone crushing, spring cone crusher, gyradisc cone crushers. JXSC Mine Machinery Factory cone crusher for sale. There are hydraulic crusher and compound cone of JXSC cone equipment. And hydraulic crusher divides multi-cylinder and single cylinder hydraulic cone crusher.

The ratio of crushing of jxsc’s cone crushing China is large, and high efficiency, low energy consumption, uniform particle sizes, ease of maintenance. Intermediate crushing and fine grinding for all kinds of ore and rock. JXSC takes no shortcuts in the manufacture and machining of Crushers, ensuring the highest quality.

The price of cone crusher isn’t sure because we recommend our equipment should on the basis of the crushing plant which customers supply. If you want to buy a cone stone crusher, and want to the price, please contact us, our engineers will give you a satisfactory answer.

About JXSC:

JXSC has been consistent in the past 40 years and serves every customer with sincerity. We have three series of machines. There are crushing machine, sand making machine, mineral processing equipment.

Our factory has an area of 10000 square meters, fixed assets of 6 million Yuan, with engineer and technical personnel covering 15% of the total staff. Through many years’ practical experience and continuous technology innovation, our company’s stone crusher, ore dressing equipment, rotary dryer, and grinding mill enjoy high popularity at home and abroad.

What is a cone crusher

The one rock crusher is a compression type of equipment. It via squeeze and compress the feed material between a moving piece of steel and a stationary piece of steel to reduce material. The material crusher by squeezing of movable vertebrae and still cone. Then the crushed material is discharged at the bottom of the equipment after they pass through the cavity.

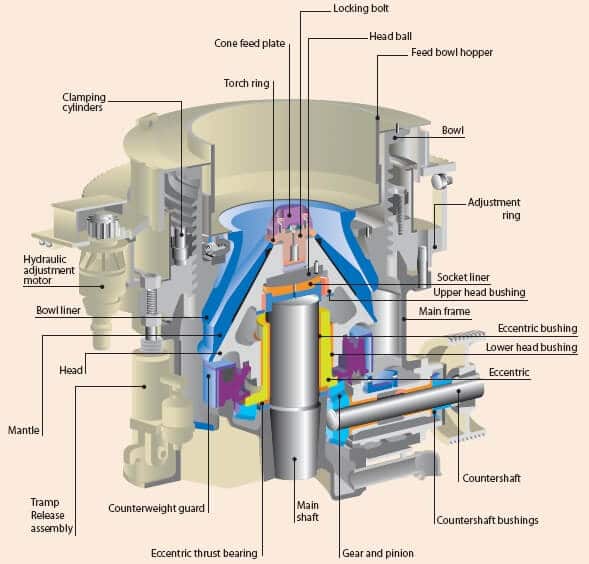

Cone crusher parts: rack, horizontal shaft, moving cone, balance wheel, eccentric sleeve, upper crushing wall (fixed cone), lower crushing wall (moving cone), hydraulic coupling, lubrication system, hydraulic system.

Cone Crusher Working Principle

When the cone crusher is working, the rotation of the motor is rotated by a belt pulley or a coupling, a cone crusher drive shaft and a conical crusher conical portion under urging of the eccentric sleeve. Therefore, the broken wall of the crushing cone is close to and sometimes leaves the surface of the rolling wall fixed on the adjusting sleeve so that the ore is continuously subjected to impact, pressing and bending in the crushing chamber to realize the crushing of the ore.

The motor drives the eccentric sleeve to rotate by the bevel gear, so that the crushing cone rotates. The crushing cone is close to and then leaves the fixed cone to complete the crushing and discharging. The joint between the support sleeve and the frame body is pressed by the spring. When the crusher falls into a non-breakable object such as a metal block, the spring is compressed and deformed to discharge foreign matter, thereby achieving insurance and preventing damage to the machine.

When the cone crushers pass through the crushing chamber or the machine is overloaded for some reason, the cone crusher spring insurance system realizes the insurance and the cone crusher discharge port increases. The foreign matter is discharged from the crushing chamber of the cone crusher. If the foreign matter is stuck in the ore, the clearing system can be used, so that the ore discharge continues to increase, so that the foreign matter is discharged into the crushing chamber of the cone crushers. Under the action of the spring, the cone crusher automatically resets the discharge port, and the cone crusher machine resumes normal operation. The surface of the crushing chamber is covered with a wear-resistant high manganese steel liner. The size of the discharge port is adjusted hydraulically or manually.

Cone Crusher vs Jaw Crusher

1. Productivity

The cone crusher has a deep crushing cavity, and the crushing process is continuous. The force exerted on the material is the result of bending force, shearing force and friction force. It is easier to be broken than the jaw crusher with the same width of the ore opening. The production capacity is more than twice as high as the jaw crushers, and the power consumption is lower.

2. Structure

Cone crushers are a smooth operation and less vibration in the production. Therefore its base weight is 2-3 times as such as the machine, the jaw is 5-10 times. However, the structure cone crushing machine is complex, with the shortcomings that high and heavy. The crusher equipment is not easy to move, and need a higher workshop. The stone crusher plant cost increases, so it is suitable for larger production capacity factory.

3. Material

Cone crushers are not suitable for crushing wet and sticky ores, jaw stone crusher do. But when crushing the sheet and strip hard ores, use jaw rock crusher needs two or more to meet the production requirements. But if use cone crushing just needs one.

4. Type of feed

Cone can feed ore in any direction and crowded with supplies. It doesn’t need to add an ore hopper and vibrating feeder. But the jaw crushing machine must feed ore uniform and not allow to feed a crowd. Therefore it needs to set another ore bunker and feeder equipment. It must need to install an expensive heavy plate feeder if the ore block size is more than 400 mm.

5. Operation

Cone crushers are easy to start, and jaw crushers need to turn the heavy flywheels to start. But the install and maintain of a cone machine is more complex.