Some customers had asked the question that can a stone crusher making artificial sand. Now, what is the difference between crusher and sand machine?

Stone Crusher

The rock crusher mainly uses to crushing large materials into small pieces. Of course, also to divide the coarse and fine crushing. In other words, the types of crusher equipment are cone crusher, jaw crusher, hammer crusher, impact crusher, rotary crusher, roll crusher. The working principle of each kind of crushing equipment is different. Also the degree, force and way of crushing the material.

Sand Making Machine

There are many types of sand-making machine, such as vsi sand making machine, mobile sand making equipment and so on. The sand maker crusher is mainly for breaking pebbles, limestone, coal gangue and other stone crushing. The machine broke the material crushing by stone crusher. The finished product material particles will be smaller, mainly the use of mechanical equipment when making sand. Sand making machine used to produce artificial sand and plaster sand.

The Difference Between Crusher and Sand Making Machine

A whole production plant will use the crusher and sand machines in general. Stone crusher used in stone production line, sand making equipment is generally used for a sand production line. In the sand-making production line, the jaw crusher is usually used for the primary crusher, and the sand making machine is used for the secondary crusher. Crusher plant also used to jaw crusher for first crushing, the impact crusher for second crushing. If the particle size of the crusher is not too small, there’s no need for second crushing. It can use the secondary crusher directly if it must use.

The feed and the discharging granularity are different. The particle size of the material broken by the stone crusher is coarse, and the particle size of the feed material is big. Feed size is generally in the 40-1000mm, some crusher model feed size can even reach 1500mm. And discharge particle size is generally greater than 5 mm. The particle size of the material broken by the sand machine is fine, feed is small. The big particle size of the feed material is generally between 6-60 mm, and the discharge less than 5 mm in generally.

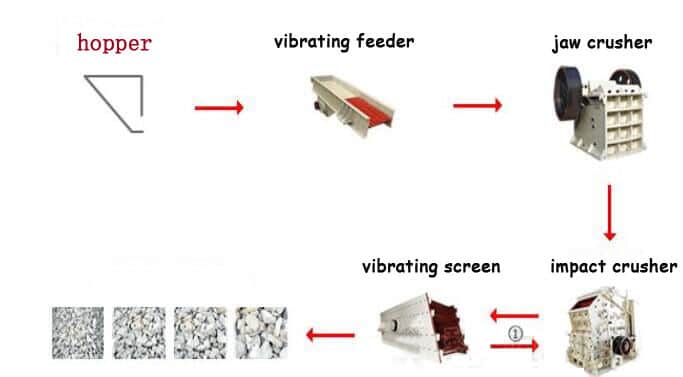

Crusher Plant

The crusher plant includes the vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor. In order to meet the different processing needs of customers, the plant can be equipped with cone crusher and dust removal equipment.

The big stones are crushed that uniformly sent to the jaw crusher by the vibrating feeder. and the coarse crushed stone is further crushed by the belt conveyor to the impact crusher The finely crushing is sieved by belt conveyor into vibrating screen, and to screen several kinds of stones with different sizes. The stones that meet the grain size requirement are transported to the finished material pile by the finished belt conveyor. The other requirement is sent back to the impact crusher to be broken again, forming a closed circuit for many times.

Rock crusher plant has a high degree of automation. The complete production plant hardly needs manual operation except for the start-up and daily maintenance of the equipment. The plant can be used for hard limestone, granite, basalt, river pebbles, metallurgical slag and other materials of aggregate, and artificial sand operations. It is suitable for the application in the industry of water and electricity, building materials, freeway, urban construction.

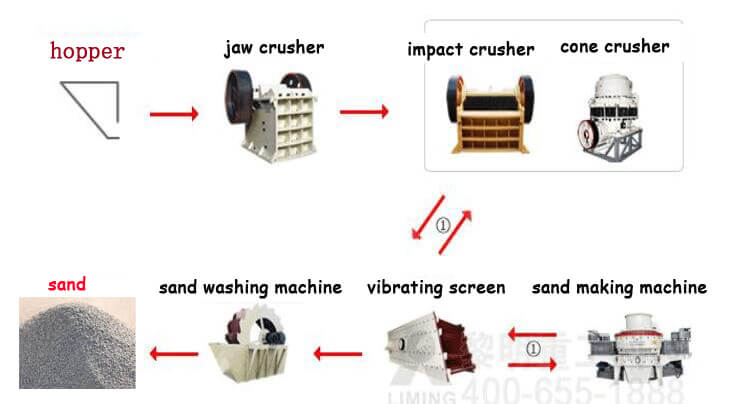

Sand Plant

The sand plant includes the vibrating feeder, jaw crusher, sand making machine, vibrating screen and belt conveyor. Crushing equipment using the material layer formed in the crushing chamber, the impact crushing and grinding between the material and the material can improve the production efficiency of manufactured sand, and reduce the production cost greatly.

The stone material is uniformly sent to the coarse crusher by the Feeder for primary crushing. Then primary crushing stones sent to impact crusher for further crushing. Some of the crushing materials screen to sand making machine by the vibrating screen, some screen is the produced sand. The materials that do not meet the grain size requirement are sent back to the sand maker by the belt conveyor to be broken again. Forming a closed circuit for many times. The finished product granularity can be combined and classified according to the user’s requirement. In order to protect the environment, auxiliary dedusting equipment can be equipped.

The equipment of sand plant widely uses for hard limestone, granite, basalt, river pebbles, metallurgical slag and other materials aggregate. It is widely used in hydropower, high-speed railway construction, building materials, freeway, city construction, human landscape, embankment and Flood Control Zone Construction and so on.