Classification of Cone Crushers

The cone crusher is basic crusher equipment of stone crushing filed, it has a wide range of applications in the construction, chemical, metallurgical, transportation, and other industries. Suitable for iron ore, non-ferrous ore, granite, limestone, quartzite, sand rock, pebbles, etc. According to the discharge demand, the cone crusher can be divided into coarse crushing and medium fine crushing; according to the structure and function, it can be divided into three types: spring cone crusher, hydraulic cone crusher, and Symons cone crusher. Characteristics and differences of various cone crusher equipment are introduced detail in below.

1. Cone crushers classification by discharge requirement

1.1 Coarse crushing

When it comes to coarse crushing, we may think of the jaw crusher in the first place. Indeed, the jaw crusher is representative of the coarse crushing equipment, and the cone crusher is also used for coarse crushing, which is called a rotary crusher. Rotary crusher is mainly used in the ore dressing industry, mainly for the coarse crushing of ore of various hardnesses. Because the machine needs to process the larger size of the block, the feed port is required to be wide, and the moving cone is upright, and the fixed cone It is inverted to meet the crushing needs of ore materials. So, what’s the difference between rotary crusher and jaw crusher?

1.1.1 Rotary crusher vs Jaw crusher

- Rotary crusher has a bigger crushing cavity, higher production capacity, compared to the same feed mouth jaw crusher, the rotary crusher is more than double that of the latter, and the power consumption per ton of ore is 0.5-1.2 times lower than that of the jaw crusher.

- Rotary crusher works stably, with light vibration, and crusher foundation weight. The basis weight of the gyratory crusher is usually 2-3 times the weight of the machine, and the basis weight of the jaw crusher is 5-10 times the weight of the machine itself.

- The large gyratory crusher can be directly fed of original ore without a mine bin and a feeder. The jaw crusher is necessary to set up a mine bin (or feed funnel) and a material feeder. When the ore block is larger than 400 mm, it is necessary to install an expensive heavy pan feeder/ apron feeder.

1.2 Medium-fine crushing

In addition to the above mentioned for coarse crushing, the cone crushers also have a type that can be used for medium and fine crushing. As far as the current situation of most of the concentrating plants in China, most of the medium crushing equipment use standard cone crushers, and most of the fine crushing equipment use short-head cone crushers. Since the basic structure and working principle of the standard cone crusher and the short-head cone crusher are identical, and the treated material block is coarsely crushed, the feed port does not need to be large, but it is required to increase the discharge range. In order to increase the production capacity, the crushed product is required to have a relatively uniform particle size. Therefore, the moving cone and the fixed cone are both upright. The moving cone is made into a mushroom shape. In the vicinity of the discharge opening, there is a parallel belt of equal distance between the moving and fixed cones to ensure uniform particle size of the discharged material. This kind of cone crusher has a small slope on the surface of the moving cone, and the material is rolled down along the slope of the moving cone when discharging. Therefore, the unloading is affected by the frictional resistance of the slope, and is also affected by the centrifugal inertia of the cone deflection and rotation. Therefore, this kind of crusher is not free to discharge, so the working principle and calculation are somewhat different from the coarse crusher.

1.2.1 Standard cone crusher VS short head cone crusher

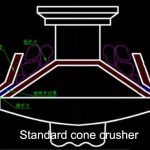

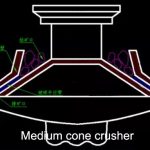

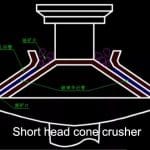

Since the basic cone crusher and the short-head cone crusher have the same basic structure and working principle, they only slightly different in the shape of the crushing chamber. Therefore, the key to the difference lies in the fracture of the parallel belt. As shown in the following figure, the short-head type parallel belt is long. Therefore, the ore supply port and the discharge port are relatively small, and a finer product particle size can be obtained. The standard type is shorter, so the crushed product is coarser and the output is higher. Generally, it is used as a medium crush after the coarse crushing or the rotary or rotary crusher.

2. Cone crushers classification by structure

2.1 Spring cone crusher

The performance of the spring cone crusher is stable. In particular, the overload protection device of the spring safety system allows the iron block to pass through the crushing chamber without jeopardizing the equipment. The unique sealing system isolates the stone powder from the lubricating oil, thereby ensuring the reliable operation of the spring cone crusher. The spring cone crusher is mainly used in quarries, stone factories, mining, etc. It plays an important role in the crushing of ore and building aggregates of various metal mines, limestone, granite, basalt and so on.

Advantages of spring cone crusher

- The moving cone is continuously rotated, and the crushing process and the discharging process work alternately, so that keeps balance in the material inlet and outlet.

- Spring cone crusher has a higher capacity compared to a jaw crusher, besides, take on a good performance on hard rock crushing task. what’s more, less cost than hydraulic cone crusher.

- Spring-safe system has an overload protection function, enhances the ability of cone crusher to respond to unexpected situations.

Disadvantages of spring cone crusher

- It is not suitable for crushing wet and sticky ores.

- It is 1.7 times heavier than the same feed size jaw crusher, 2-3 times higher than the jaw crusher so that increases the installation and maintenance cost.

2.2 Hydraulic cone crushers

The hydraulic cone crusher is developed on the spring cone crusher. It is divided into two series, HPC series hydraulic cone crusher and HCS series hydraulic cone crusher. The production capacity and the crushing efficiency are greatly improved, and the application range is also expanded. The hydraulic cone crusher is rotated by a rotation of the electric motor through the pulley or the coupling, the transmission shaft and the conical portion under the eccentric sleeve. Therefore, the crushing wall of the cone crusher is close to and then leaves the surface of the white wall fixed on the adjusting sleeve, so that the ore is continuously subjected to impact, pressing and bending in the crushing chamber to realize the crushing of the ore.

Advantages of hydraulic cone crusher

High crushing ratio, high production efficiency, low consumption of vulnerable parts, low operating cost, hydraulic protection and hydraulic cavity cleaning, a high degree of automation and reduction of downtime.

JXSC provides a full of stone crushers, include cone crushers, impact crusher, hammer crusher, jaw crusher, roller crusher, and laboratory ball mill. contact us to know the latest stone crusher machine price.