How to Improve the Production of Sand Making Machines?

The sand making machine is suitable for the crushing task of soft or medium hard and extremely hard materials. It is widely used in various ores, cement, refractory materials, aluminum soil clinker, corundum, glass raw materials, mechanism stone materials, gold slag, especially for High-hardness, extra-hard and abrasion-resistant materials such as silicon carbide, silicon carbide, sintered bauxite, and fine sand have higher yields than other types of crushers.

The sand making machines also called stone crusher. It is widely used in medium and hard materials such as granite, basalt, limestone, quartz, gneiss, cement clinker, concrete aggregate and ceramic raw materials. Iron ore, gold, copper, corundum, bauxite, silica, etc. It can be applied to fine crushing and super fine crushing operations in industries such as artificial sand making, pre-grinding cement, mining and refractory materials with a great difference in material properties.

Variable effects production of sand making machines

Vertical shaft impact crusher is a new type of crushing equipment, very popular in the field of sand making at home and abroad, also known as sand making machine. In general, there are many factors affecting the production capacity of impact sand making machines, mainly from the following five aspects: material characteristics, impeller speed, crusher operating parameters, production line design and operation and maintenance.

1. Ore material

- Material hardness

The main factor affecting the crushing production process is the hardness of the ore itself. The crushing effect of sand making machines is inversely proportional to the hardness of the material. The higher the hardness is, the more difficult the crushing is, the lower the efficiency is, and the more serious the loss of the equipment is. - Size of input granules

Each stone crusher defines the maximum particle size of the feed. If input material size is too large, easy to cause the blockage, thus damage the crushing function. besides, and the excessive amount of fine powder contained in the material will also affect the sand production. For materials with a high content of fine powder, sieve it in advance and screen it out to avoid affecting the normal operation of the equipment.

While ensuring the sand making machine production, a suitable feeding amount is beneficial to increase the life of the wearing parts. When the feed amount reaches 70%~90% of the impeller full load, the sand production reaches a peak. If the feeding amount is too small, not only the output of the equipment is reduced, but also the wear amount of the crushing chamber liner and the like is increased, and the replacement period of the fitting is shortened. - Material humidity

When the moisture contained in the material is large, the material is easy to adhere in the impact sand making machine, and it is easy to cause clogging during the feeding process, which causes the sand discharging ability to decrease. If the humidity of the selected material is too large, you can use sunshine or air drying to reduce the percentage of moisture in the material. - Material viscosity

The greater the viscosity of the material, the easier it is to adhere. The material with high viscosity will adhere to the inner wall of the flow channel cavity in the impeller and even block the flow channel. If it cannot be cleaned in time, it will affect the working efficiency of the sand crushing machine, and may affect normal work in severe cases. Therefore, when selecting materials, should choose a low viscosity.

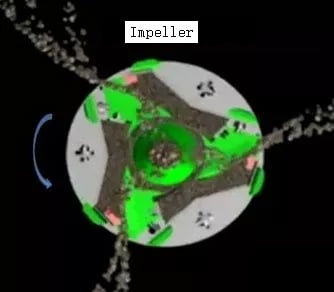

2. Impeller speed of sand maker

The continuous material enters the high-speed rotating impeller, be crushed in the crushing cavity under high-speed extrusion, grinding and crushing procedure. From the working principle of the vertical shaft impact crusher, when the particle size of the material has been determined, the kinetic energy increases greatly with the increase of the linear speed of the crusher rotor; when the crusher rotor speed is balanced, if the material quality increases, the kinetic energy It also increases, and vice versa.

There is a certain relationship between the particle size of the broken shaft and the linear velocity of the rotor. Under the premise of the same working condition, if the particle size of the crushed material is large, the linear speed of the crusher rotor is low. Therefore, it can be seen that when the material crushing strength is large or the crushing particle diameter is small, the required crushing speed is increased. When the particle size, water content and feed amount of the incoming material are the same, the rotor speed (line speed) of the crusher is appropriately increased, and the output of the fine powder is improved.

3. The capacity of the sand manufacturing plant

The crusher function and structure have a great impact on the crushing effect. The type and specification of the crusher, the economic rationality of the installed power, the suitable range of the speed, the size of the discharge port and the structural form of the crushing chamber all have a great impact on the crushing efficiency.

For example, the crushing chamber of the vertical shaft impact crusher can be divided into a stone type and iron type. The former has better grain shape and is suitable for shaping; the latter has high crushing efficiency, but the finished grain type is slightly worse. The wear cost of the peripheral shield is also high.

Changing the form of the peripheral lining plate in the crushing chamber, or increasing the iron counterattack plate, increasing the size of the discharge port of the crushing chamber, etc., can increase the production amount, and the amount of fine particles of the granules increases remarkably.

4. Sand making plant flow sheet design

Efficient sand making production line not only requires high-efficiency sand making equipment, but also coarse, medium-breaking, screening washing equipment, wastewater and mud processing equipment to meet capacity requirements. If a certain link does not reach the required crushing ratio, it will inevitably cause pressure and restriction to the next level of crushing, which will cause an increase in the system failure point, which will reduce the operational reliability, and finally, the sand production amount of the sand making machine will also be declined.

5. Operation and maintenance of sand maker

The standard operation and regular maintenance of the sand making machine will also affect the sand output of the equipment. If sand making machine is not standardized during operation and does not perform regular maintenance, it will cause the wearing parts of the equipment to wear faster, the life of the equipment is greatly reduced, and the production volume per unit time is small.

The vertical shaft impact crusher is a widely used sand making equipment on the market. The capacity of the vertical shaft crusher is not only related to the equipment itself, but also closely related to materials, operation and maintenance, and the configuration of the production line. Users should add more comparisons in the early stage of purchase, and choose a regular and powerful manufacturer planning and design production line.

JXSC sand making machine for sale, we provide different types of sand making machines and mobile sand making machine for crush sand plant, contact us to get the latest sand crusher machine price and artificial sand making process flowsheet PDF file.