In the sand and gravel production line, especially in the wet sand production line, in order to improve the quality of the finished sand, sand washing is an essential link. Through the washing function of the sand washing machine, the dust on the surface of the sand and gravel can be effectively removed, and the quality of the finished sand and gravel can be improved. At present, the sand washing machines used in the market mainly include spiral sand washing machines and wheel bucket sand washing machines.

Sand Washing Machine

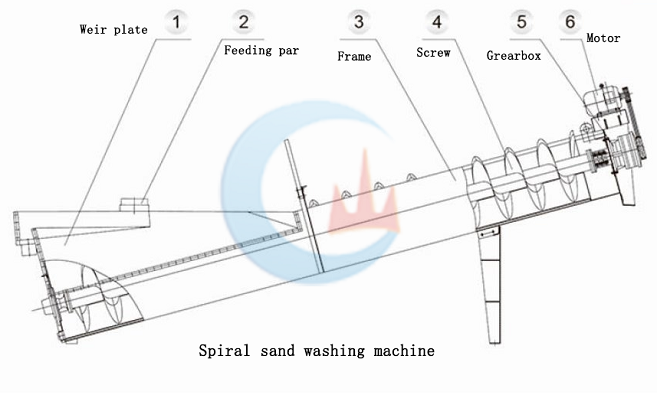

Spiral sand washing machine is mainly used for washing, grading, impurity removal, and fine-grained and coarse-grained material washing in highway, hydropower, construction and other industries;

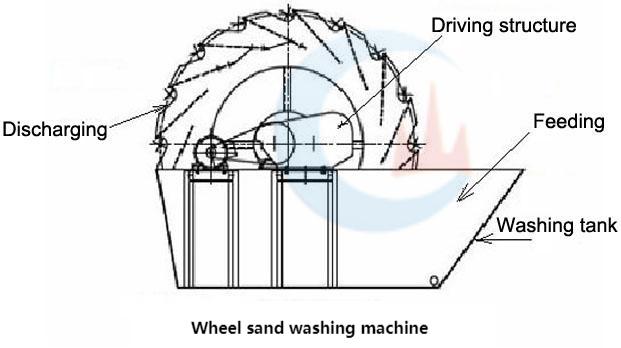

Wheel bucket sand washing machine is widely used in sand and gravel fields, mines, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station and other industries for the washing of materials.

Wheel Sand washer VS Spiral sand washer

1. Distinguish from the principle of sand washing

During operation, the motor of the wheeled sand washer drives the impeller to rotate slowly after deceleration through the V-belt, the reducer and the gear, and the sand enters the washing tank through the feeding tank. Driven by the impeller, they roll and grind each other to remove the impurities covering the surface of the sand and at the same time destroy the water vapor layer covering the sand to facilitate dehydration. At the same time, add water to form a strong water flow, take away impurities and foreign objects with small specific gravity in time, and discharge them from the overflow washing tank to complete the cleaning effect. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured into the discharge chute from the rotating impeller to complete the cleaning of the sand and gravel. Because the transmission part of the wheel sand washing machine is isolated from water and sand, its failure rate is much lower than that of the sand washing equipment commonly used in the current market, so it is a good choice.

|

|

2. Analysis from the appearance structure

The wheel-type sand washing machine has a simple structure, few wearing parts, and a small footprint. The impeller drive bearing device is isolated from water and water-receiving materials, which basically avoids the phenomenon of bearing damage caused by water, sand and pollutants, and greatly reduces the failure rate.

The spiral sand washing machine is relatively narrow and long, and adopts a horizontal structure, which is simple and straightforward, but the installation and arrangement are not as convenient as the wheel type.

3. Analysis of sand loss and cleanliness

The wheel sand washing machine uses less water in the sand washing process, and the loss of fine sand and stone powder is small, and the gradation and fineness modulus of the washed construction sand can meet the standard requirements.

The spiral sand washer will filter part of the fine sand during the cleaning process, so it seems that the sand washing will be particularly clean.

4. From the analysis of cleaning ability

The cleaning of the sand and gravel by the wheel sand washing machine is to remove the dirt and other impurities wrapped on the sand. After being cleaned by a wheeled sand washer, the water vapor layer on the surface of the sand can be destroyed, so that the water can be removed as quickly as possible to achieve the cleaning effect required by the construction. However, the processing capacity is relatively small, the loss of sand during the cleaning process is small, and there is no need to use too much water resources. It is generally suitable for sand production lines with small and medium production capacity.

The spiral sand washing machine has strong cleaning ability, higher power utilization rate, and high cleaning degree. It can clean fine-grained stones, and can clean gravel with serious mud. It can also effectively clean sand and gravel with serious mud impurities, and is often configured in large sand production lines.

5. Application Scope

The wheel bucket sand washing machine is widely used in washing, grading, impurity removal and other operations in metallurgy, building materials, hydropower and other industries, and is suitable for washing and sorting of fine-grained and coarse-grained materials. However, the wheeled sand washing machine makes full use of the abandoned pebbles and limestone resources by the river, which can increase the amount of sand washing and reduce the cost of sand making, and fully protect the natural sand and gravel resources, which is no problem for environmental protection.

The spiral sand washing machine is especially suitable for the production of abrasives, refractory materials, cement, quartz sand, steel sand, slag powder, copper ore, gold ore, concrete aggregate, asphalt aggregate and other hard and brittle materials. , is a high-efficiency and energy-saving crushed stone sand making equipment, which can save 50% energy than traditional sand making machines. It is suitable for the washing operation of medium-fine-grained and coarse-grained materials, and is used for washing, grading, impurity removal in industries such as highways, hydropower, and construction, as well as fine-grained and coarse-grained materials washing and other operations.

6. Distinguish from equipment price

The price of wheel sand washing machine equipment is relatively low, it is an economical and efficient sand washing machine type, and its operating cost is also low.

The price of spiral sand washing machine equipment is relatively high, and it belongs to the type of high-end and large-volume sand washing machine.

JXSC Sand Washing Machine Advantage

1. Low sand loss rate: The sand washer has a low sand loss rate during the sand washing process, ensuring high-yield sand washing operations.

2. Customizable: The screen of the sand washing machine can be customized according to the actual needs of users, so that your investment income ratio can be higher.

3. High-quality sand products: The equipment is equipped with traditional devices, which can realize repeated feeding and repeated cleaning. The washed sand has high cleanliness and higher standards, and can be sold at a good price.

4. Long service life: The impeller drive bearing device of the wheel-bucket sand washing machine has no contact with water, materials and pollutants, which can effectively avoid the corrosion and wear of parts and prolong the service life. Consumable parts screen replacement cost is low.

5. Save water resources: JXSC sand washing machine can reuse water resources, and the sand washing water can be recycled in combination with the sedimentation tank, and the water after sedimentation can be repeatedly washed for sand materials. The precipitated sludge can be directly used in mine reclamation, saving you operating costs.

To sum up, it is not difficult for us to choose between wheel sand washers and spiral sand washers. We will determine the composition of the sand and gravel, the estimated production capacity, the conditions of the production site and other factors. Both types of sand washing machine equipment have their own characteristics. Only by choosing the one that suits your production requirements can you obtain better economic benefits. Contact JXSC to custom sand washing machine and get the factory price!