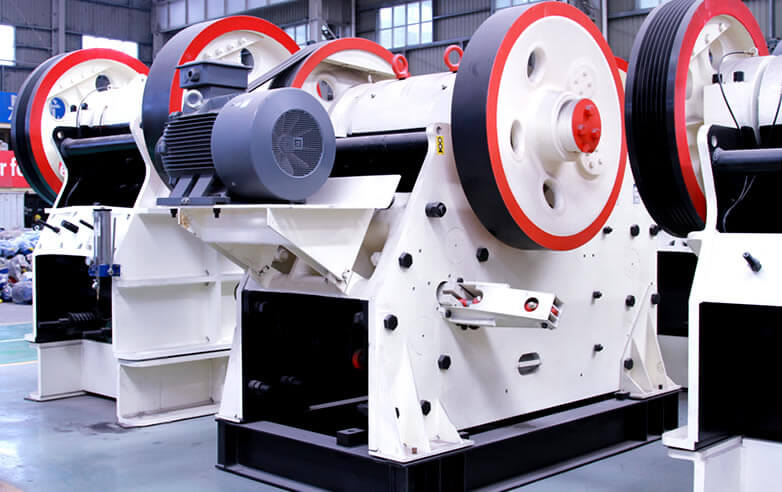

Jaw Crusher Handbook

JXSC Mine Machinery Factory is crusher manufacturers and jaw crusher for sale. Jaw crusher is a kind of rock crusher equipment. This jaw crusher handbook that we hope can help you to learn more about the stone crusher.

jaw crusher working principle

When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft. The angle between the bracing plate and movable jaw gets bigger when the jaw rising. Then pushing the jaw close to the fixed jaw-crusher plate, achieve the crushing aim when the materials were crushed. The angle between the bracing plate and movable jaw getting smaller when the jaw down.

The moving jaw leaves the fixed jaw plate under the action of the pull rod and the spring. Crusher stone discharge from the bottom of the crushing cavity. Crusher machines’movable jaw doing periodic crushing and discharging with motor rotates continuously. Then realize continuous production.

Installation and Adjustment

1. The crusher is installed on the pre-made Foundation (the foundation should be well laid), the crusher finds a good level. The base plate and the foundation are left about a 20mm gap filled with cement mortar. Then tighten the nut of the base bolt when the mortar stiffness. Starting up after complete hardening of mortar.

2. If Not cement mortar, can also be the foundation and crusher base on the middle cushion of the moderate hardness of wood (the whole bottom), as a shock pad; Screw the foundation and base can be used.

3. The belt pulley groove of the motor and crusher machinery must be the same, parallel to the installation, belt tightness suitable.

4. The size of the discharge port is adjusted by adjusting the pull iron at the tail of the machine. The pull rod discharge port of the lifting pull iron is smaller, and the lower pull rod discharge port is larger.

Safe Operating Procedure

1. Before starting, all jaw crusher parts must be fastened installed. The tail traction spring is suitable loose, and the engine oil is installed in the swing bolster.

2. Jaw rock crusher must test run 2 hours when first start-up. It can be fed to work after the bolster temperature below 600. After that, a start-up can work.

3. Jaw crushers must be started with no-load.

4. Check that all the instruments are in good condition.

5. Check the crushing cavity have or not Minerals and other non-crushing materials.

6. The degree of tightness of triangle belt and locking spring must be moderation.

7. Crusher installation, it is necessary to configure a good reliable pulley and flywheel safety cover.

8. During the operation of the machine, no person may stand in the rotating surface of the jaw crusher.

9. During operation, personnel shall not use their hands to retrieve large pieces of ore or other items that enter the machine.

10. The materials must be discharged before the jaw stone crusher stop working.

11. The feeding specifications of jaw crusher shall not exceed 0.85 times the size of the feeding port.

12. Stop the feeding system before stopping.

Exigency stopping case

1. The temperature of the main bearing or the movable palate shaft suddenly rises above 80 °C, the surface phenomenon is 2. that the back of the hand touches the bearing seat cannot last for one second.

3. The front or rear thrust plates fracture.

4. Belt Bolts or other transmission pieces may be loose and broken when flying injury.

5. Motor Smoke.

Watch over when running

1. All departments give an oil (grease) to keep normal.

2. Bearing temperature not exceeding 60 °C.

3. No abnormal changes in electrical instruments.

Lubrication

1. Regular attention and timely finish the friction surface lubrication work, ensure the normal operation of the machine and extend the service life.

2. Jaw crusher equipment generally uses calcium-based grease. Users can also use other types of grease according to the location of the machine, temperature and other conditions to choose. But it must ensure the bearings with a good lubrication.

3. The Grease added to the bearing housing is 50-70% of its volume and must be replaced every three months. When changing oil, carefully clean roller and bearing slideway with clean gasoline or kerosene.

4. The contact point between the Elbow Plate and the elbow plate pad must be greased before the machine is started.

Jaw crusher maintenance

①The main engine suddenly stopped

Reason:

1) The discharge port block, resulting in a full cavity block material;

2) The v-belt driving the grooved pulley turns too loose, causing the belt to slip;

3) The eccentric shaft fastening bushing loosens, causes in the frame bearing housing both sides to have no clearance, causes the eccentric shaft to be stuck, cannot rotate;

4) The working place voltage is too low after the main engine meets the big material, unable to break;

5) Bearing failure.

Solution:

1) Remove the blockage of the discharge port to ensure the smooth discharge;

2) Tighten or replace the v-belt;

3) Reinstall or replace the fastening bushing;

4) Adjust the voltage of the working place to meet the requirement of the working voltage of the main engine;

5) Replace bearings.

②The Geneva wheel of the main engine and moving jaw smooth operation, but the crushing work stops

Reason:

1) The extension spring breaks;

2) The pull Rod broke;

3) The elbow plate falls off or breaks.

Solution:

1) Replace the tension spring;

2) Replace the pull Rod;

3) Reinstall or replace the Elbow Plate

③ The output is not up to factory standard

Reason:

1) The hardness or toughness of the crushed material exceeds that specified in the operation manual;

2) The connection position of the motor is reversed, the main engine is reversed (the moving jaw rotates clockwise), or the triangle connection of the motor is formed into the Star Connection;

3) The discharge opening is less than the prescribed limit;

4) The jaw plate is displaced and the top of the tooth is opposite to the top of the Tooth;

5) The voltage of the working site is too low;

6) The clearance between the movable jaw and the bearing is too large, which causes the bearing outer ring to rotate relatively.

Solution:

1) Replacement or addition of rock crushers;

2) Switch motor connections;

3) The discharge opening is adjusted to the nominal discharge opening specified in the specification and a crusher for fine crushing is added;

4) Check the tooth distance of the tooth plate, if not in accordance with the standard, replace the jaw plate. Adjusting the relative position between the fixed jaw plate and the movable jaw plate to ensure that the tooth top is fixed and pressed against the tooth root to prevent displacement.

5) Raise the voltage of the working place to meet the heavy load requirement of the host machine;

6) Replace bearings or jaws.

More about jaw stone crusher machine problems. Please contact us that our engineer solves it for you. Or ask for the stone crusher machine price.

Jaw crusher wears parts: 1. Side Plate 2. Fixed jaw plate 3. Movable jaw plate 4. Support Plate 5. Lining Iron

>>>>>> Walkpump handbook