The sand washing machine is sand (artificial sand, natural sand) washing equipment. Which widely used in sand and gravel field, mine, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station, etc. There are two types: wheel sand and spiral sand-washing machine. What is the sand washing equipment working principle?

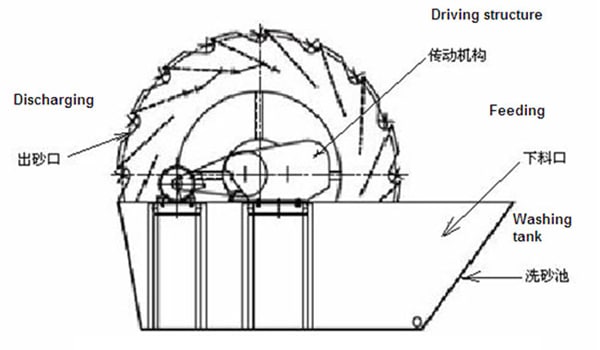

Wheel Sand Washing Machine Working Principle

The bucket wheel sand washer cleans and separates stone powder and dust. It’s novel seal structure and reliable gearing ensure the cleaning and dehydration effects. The sand washer is a kind of high-efficiency sand washing equipment operated with the sand maker. This series of sand washer features the following advantages: rational structure, convenient maintenance, great handling capacity, low power consumption, and high washing cleanliness.

Working principle: When it works, the power plant drives the impeller to slowly rotate after slowing down through the V-shaped belt. Sand from the feeding trough into the wash trough, in the impeller driven by rolling. And mutual grinding, get rid of the cover the surface of sand impurities. The water vapor that covers the sand is destroyed to facilitate dehydration. At the same time, add water, a strong flow of water, timely impurities and the proportion of small foreign bodies away. And discharge from the overflow washtrought to complete the cleaning process.

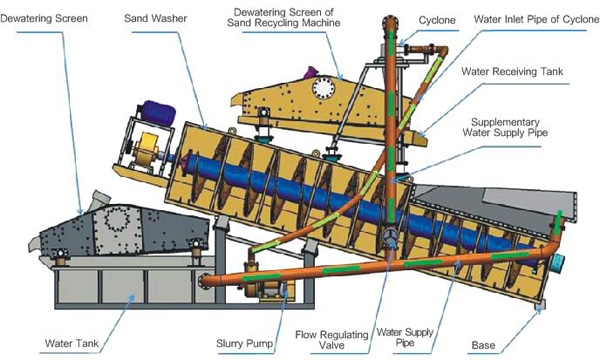

Spiral Dand Washing Working Principle

The spiral sand washing equipment is suitable for construction sites, sand factory, hydropower station, concrete dam site, post and telegraph pole factory. The required users’ sand and casting with “70” sand, glass quartz sand, oil filling pressure sand washing, grading and dehydration. The sand washing machine according to a 15 ° tilt arrangement, the lower of the water tank is composed of three side weir plates formed by a sedimentation tank. Screw head into the settling tank, spiral by a motor through reducer drive continuous rotation, clean water into the porous plate from the bottom of the tank. This equipment has three functions: cleaning, dewatering, classify.

Working principle: the principle of the spiral sand washer is size or proportion of different solid particle settling velocity in the liquid is different, fine mineral particles suspended in water or overflow, coarse particles sink to the bottom. The spiral discharged from the up is a kind of classification equipment for mechanical grading. Milldischarging through the filter, coarse material is screwed into the mill inlet using on-chip spiral vane, the fine filter out from the overflow pipe. The base of the machine adopts a channel, the body adopts a welded steel plate.

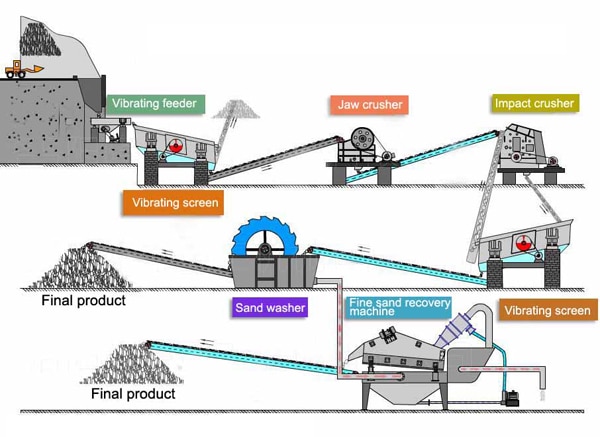

Sand Washing Process

The sand washing plant is composed of jaw crusher, sand making machine, sand washing machine, and belt conveyor. Its technology is that the stone materials are uniformly sent to jaw crusher by vibrating feeder for crushing. Then the primary crusher material sent to sand crusher machine by belt conveyors for further crushing. The finely crushed material is sent to the vibrating screen for screening. The material meets the requirements of the finished product size is sent to the sand machine for cleaning After cleaning. The finished product is exported by the conveyor belt. The materials that do not meet the requirements of the finished product size are returned from the vibrating screen to the sand machine for re-processing, forming a closed circuit for many times.

In the production of machine-made sand, the sand washed by the sand washing is cleaner and of better quality. The machine has gradually become an important equipment of the artificial sand production line. The following issues require our attention.

Installation Requirements

1. After the equipment arrived, the user unit should check whether the parts are complete and no damage immediately. Make sure it is intact before you install it.

2. The unit shall design the basic construction drawing of the sand washing machine according to the specific situation on the spot. And install the sand washing machine firmly on the solid concrete foundation.

3. The spiral sand washing installation must be in accordance with the requirements of the installation diagram to ensure the tilt angle.

4. The motor is installed on the guide rail to adjust the tightness of the belt. The belt pulley and the motor pulley should be parallel during the installation.

5. According to the above requirements, the rotor disk rotation several rotations, to check it whether stuck, collision phenomenon.

Operating Notes

1. Before starting the sand washing plant, check whether there are sundries in the drainage hole and the sewage hole. Clean up in time to prevent the drainage hole and the sewage hole clogging.

2. Check that all fasteners are fully secured and nuts tightened, especially the new one.

3. Check whether the oil is high. If not up to standard, we should add the oil in time.

4. Check the belt sander is good. If found belt damage should be replaced, and belt oil should be wiping it.

5. Check the protective device is in good condition if found unsafe phenomenon should be removed in time.

6. After starting, the sand washing equipment out of order, stop it immediately.

7. Allow starting without load.

8. When washing sand, first open the washing water pipe, then feeding the material. At the same time, adjust the direction of the water jet and the height of the overflow baffle, make sure it can effectively wash sand and maintain a proper water surface. Just the right amount of water can be cleaning sand and not overflow. Feeding should even, not too much too fast, too much will easily make the machine because of overload to damage, too little will affect the output.

9. When stops, it should be carried out in sequence. Forbidden to stop the machine with material or to continue feeding after stop.

Maintenance

1. Bearing is the most easily damaged part. Regular oil maintenance can increase service life.

2. Generally, every two months to check the work, wear and tear should be replaced immediately. When using the sand washing machine with rolling bearing, the bearing housings at both ends of the spiral shaft should be checked frequently. The reliability of the bearing sealing device should be noted. If you find it wears, water seepage, sand immersion, and other phenomena, the machine should be stopped immediately. Replace seals and clean and lubricate bearings. In general, rolling Bearings oils every 5000 hours.

3. In daily use, we should always pay attention to whether the machine has noise. And observes the screw shaft, triangle belt, sealing device, water pipe, and other parts. Check whether the motor and gearbox are overheated. Whether the various parts of the bolt fastening.

4. Gearbox in the operation of 3-6 months to clean and change the oil. Bearing every 6-12 months to replace the new grease.

5. Sand washing equipment seasonal maintenance is also very important. Mainly replacement of oil, fuel, antifreeze, and increase refrigeration facilities.

6. When it working, it forbade someone to stand beside it and touch the machine body to adjust, clean, overhaul and other operations.

Sand Washing Machine for Sale

JXSC is a sand washing plant manufacturers which set up in 1985. We are professional research, manufacturing, sales, and home tracking service as one of the metallurgical mineral processing machinery and equipment enterprises. We have a good reputation in the industry because of the product quality, reliable performance, good after-sales service.

On the side, if your crusher plant, mineral processing plant or sand plant needs to use the pump, we also have various pumps. >>>>>> Walkerpump