The customer from Ethiopia who came to China looked limestone crusher equipment. He contacted us and want us could design a rational solution for their limestone crusher plant. Let us view the solution to our engineer.

First, we must know some situation about the crushing plant. The stone material is limestone that maximum feed size is 250mm. The request of Ethiopia customer:

1. Throughput: 10T/H

2. The crushing limestone needs screening three sizes, 0-3mm, 4-8mm and 9-12mm.

3. Equipment: stone crusher machine, vibrating screen, Hooper, belt conveyor and control cabinet.

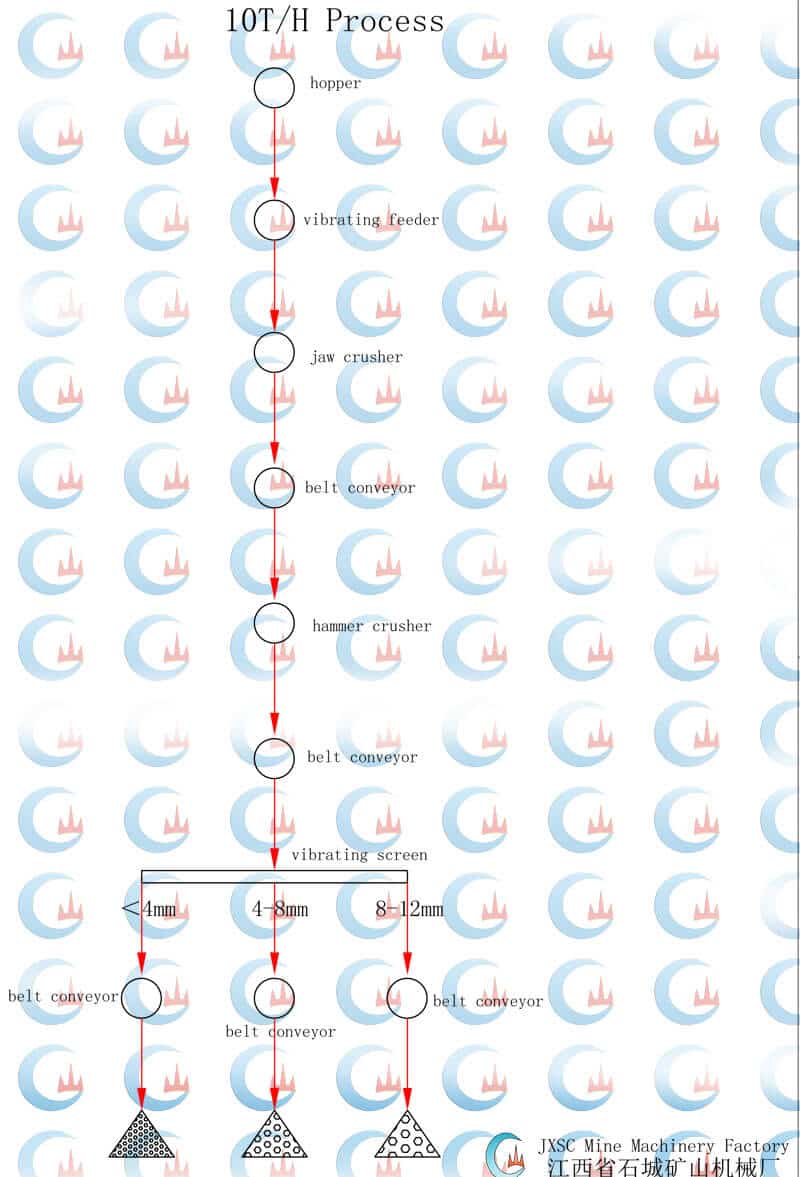

Our engineer designed the solution of limestone crusher plant.

The limestone put into a vibrating feeder from a hopper, then feed into the jaw crusher by vibrating feeder. Jaw crusher as primary crusher for limestone, then the crushed aggregate via belt conveyor transport into hammer crusher to secondary crushing. The limestone crushing process is accomplished. Next step is to screen the secondary crushing materials. Also, need incline conveyor. Then use the double-deck vibrating screen to make the three required sizes.

Jaw Crusher

The crushing machine breaking stone particle uses compressive force. And it is mainly used as coarse crusher and middle crusher in the industry of mine, building, construction .etc. Jaw crushers are classified on the basis of the position of the pivoting of the swing jaw. Swing jaw fixed at the upper position is the blake crusher. The lower position is dodge crusher, the intermediate position is a universal crusher. And there are two types of blake crusher, single toggle and double toggle jaw crusher.

Jaw rock crusher price isn’t expensive, and simple construction, steady operation, the equipment size is small, large feed port, adjustable discharge port. But jaw crushing is a heavy duty machine and hence need to be robustly constructed.

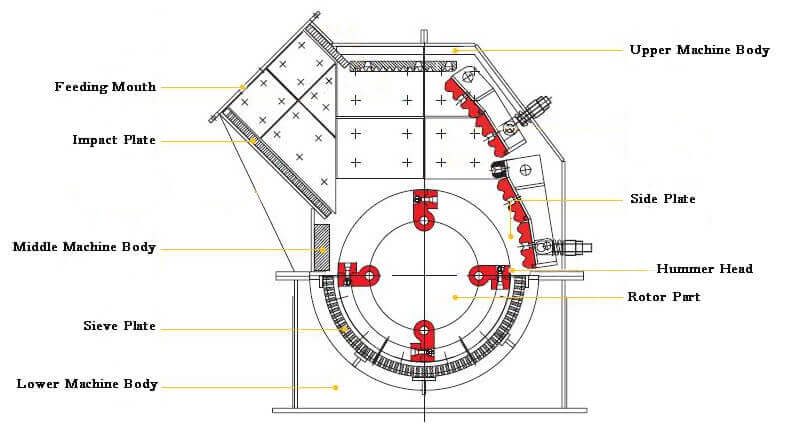

Hammer Crusher

A hammer crusher is a crusher in which a hammer hits the material that is being crushed. In the hammer crusher, crushing takes place by impact between the hammers and breaker plates. The equipment consists of feeding mouth, impact plate, middle machine body, sieve plate, lower machine body, upper machine body, side plate, hammer head, rotor part.

Hammer crushers use to break the materials that medium hard and abrasive weak, for example, coal, gypsum, brick, limestone. The compressive strength < 100 mpa, humidity < 15% of crushing materials.

Vibratory Feeder

The vibrating feeder uses both vibration and gravity to move material. The vibratory machine design of used double eccentric shaft exciter. Make sure the equipment can bear the impact of fall big materials. The machine can even, timing, continuous feeding materials from a storage bin at production processing. So that the machine will not system halted, and lengthen the use of life. There are three types of vibrating equipment: vibrating grizzly feeders, electromagnetic vibrating feeder, screw feeder.

GDN series of JXSC(vibrating feeders manufacturers) china vibrating grizzly feeder adopted japan vibration motor. The series feed big material before primary crusher, under grizzly screen effect at the same time. It can be screening away fine material such as soil.

Vibratory Screen

The vibratory screening machine is to utilize reciprocating vibration of the vibration generator produced. The processing of the screen separates the different size material by single- or triple-deck screen. Screening is an important part of rock stone processing.

Belt Conveyor

Belt conveyor has the advantages of the big conveying amount, simple structure, convenient maintenance. Almost every step of the complete mineral processing circuit is connecting by the conveyor system.

The advantages of belt conveyors: high capability at low cost, flexibility, easy to maintain.