Cone Crushers

Cone crushers have three types, single-cylinder, multi-cylinder, and compound crusher machine. Compound series cone crusher is a comprehensive cone crusher with spring and hydraulic cylinder. The cone stone crusher equipment is easy to the identification. But the single-cylinder crusher and multi-cylinder crusher, which both are hydraulic cone crusher, many people have a bit difficult to distinguish them. This article analyzes the difference between single-cylinder and multi-cylinder cone crusher from 10 aspects. Such as structure, adjustment device, lubrication system, wear parts, crushing effect. . .

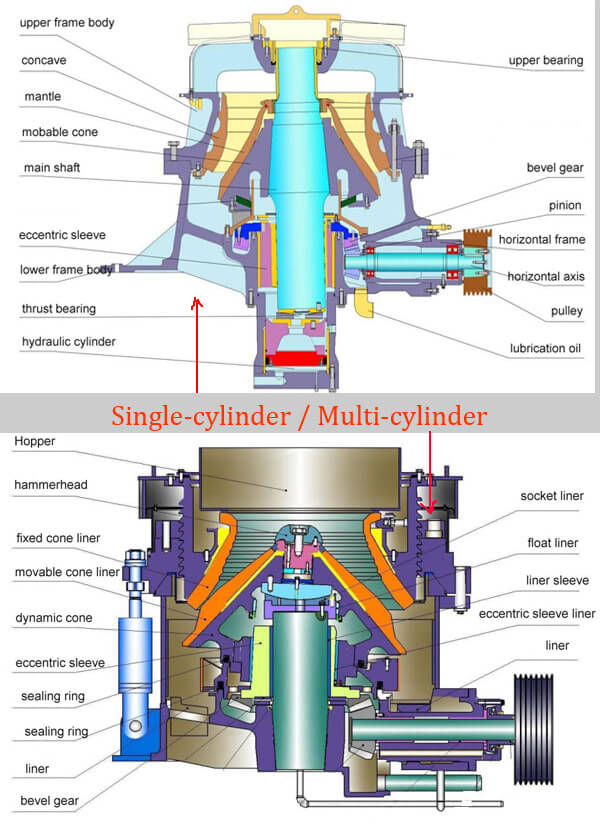

1. Structure

6 main parts of single-cylinder hydraulic cone crusher

1) Upper frame parts: upper frame, rolled mortar wall, spacer, upper frame backplate.

2) Lower frame parts: lower frame, lower frame guard plate, lower frame inner lining plate, eccentric bushing, sealing barrel.

3) Movable cone parts: spindle, movable cone body, rolling mortar wall.

4) Transmission shaft parts: sheave, transmission shaft, bearing, transmission shaft frame, small bevel gear.

5) Eccentric sleeve parts: balancing weight, eccentric sleeve, large bevel gear, mainshaft bushing;

6) Hydraulic cylinder parts: middle and lower frictional disk, hydraulic cylinder block, cylinder sleeve, cylinder bottom, displacement sensor.

6 main parts of multi-cylinder hydraulic cone crusher

1) Lower frame parts: rack, main axle, guide pin.

2) Eccentric sleeve parts: eccentric sleeve, balance ring, large bevel gear.

3) Transmission parts: transmission shaft, small bevel gear, shaft sleeve.

4) Support sleeve parts: support sleeve, lock cylinder, lock nut.

5) Adjusting ring parts: adjusting the ring and rolled mortar wall.

6) moving cone parts: body, crushing wall, hammerhead, etc.

2. Discharge port adjusting device

When the single-cylinder cone crusher operation normally, the spindle oil cylinder adds and dischargers oil is via oil pump. Then the spindle moves up or down to adjust the size of the discharge port. This adjustment way may cause the discharge outlet to be more difficult to lock when crushing the hard ore. A multi-cylinder cone crusher is through a hydraulic pusher or hydraulic motor to adjust. It drives the adjustment ring in the support sleeve rotation to achieve the adjustment. The advantage of this adjustment way is that the outlet is easy to lock.

3. Over-load protection

Single cylinder over iron and cavity cleaning. As the iron over iron, hydraulic oil adds into the accumulator, and the spindle drops. After over iron, the accumulator will press the oil back, and the crusher will run normally. It also uses hydraulic pump when clean the cavity.

Overload protection of multi-cylinder. When the unbreakable foreign body passes through the crushing cavity or due to some reasons, the machine overloaded. The hydraulic safety system realizes the protection. The discharge gate increases, and the foreign matter discharges from the crushing cavity. If the foreign body gets stuck in the discharge port, the cavity cleaning system can be used which lets discharge ore mouth further increase. Then the foreign body discharge crushing chamber. Under the action of the hydraulic system, the ore discharge gate is automatically reset and the machine resumes normal operation.

4. Lubrication system

The single-cylinder lubrication system adds oil by two oil inlet. One adds from the bottom of the main shaft into the ball bearing, frame bushing, rack bushing, main shaft bushing, and then lubrication of the small and large bevel gears. The other way is add from transmission shaft, lubrication the transmission shaft bush. At last, the two-way oil discharge from the same outlet.

A multi-cylinder lubrication system also has two ways. One is after entering the machine through the lower oil hole which divided into three branches after reach the central spindle. Another adds way from the hole on the transmission shaft rack to lubrication transmission bearings. Its oil return is through the small bevel gear lower oil return hole and dust cover oil return hole.

5. Crushing force part

The single cylinder hydraulic cone crusher is similar to the spring cone crusher, the main shaft is combined with the dynamic cone. At the same time by the bowl bearing. Therefore, the spindle and the dynamic cone equivalent to the base support, eccentric sleeve drive spindle to provide crushing force. The spindle of multi-cylinder crusher is thick and short. The diameter can be designed to be large enough to stand directly on the rack (rather than inside the eccentric sleeve) . It is directly supported by the frame to provide higher bearing capacity, and the eccentric sleeve directly drives the cone to provide crushing force.

6. Counterweight Block

The single cylinder counterweight is heavy and thick. Because when the single cylinder cone crusher work, the spindle, and dynamic cone move to the tighten edge. The thick side of the eccentric sleeve is at the wide edge, at which point the center of gravity of the whole moving cone deviates to the tighten edge. Therefore, it is necessary to add a counterweight on one side of the eccentric sleeve to balance the whole dynamic cone. In addition, the counterweight is added to make the moving cone easier to move toward the wide mouth edge.

The multi-cylinder counterweight is heavy and thin. Because the spindle of the multi-cylinder cone is fixed, so the weight block only to consider the eccentric sleeve.

7. Feeding

In general, single-cylinder and multi-cylinder hydraulic cone crusher can be full feed. The latter has no problem in achieving full feeding with high bearing capacity and can utilize the lamination principle. Aggregated rock crushing in the crusher cavity, and mutual extrusion at the same time. Crushing at the same time have shaping effect, so it is very good particle shape.

8. Crushing effect

The multi-cylinder hydraulic cone crusher has high content of fine material, better fine crushing effect and good laminating crushing effect. But the single -cylinder intermediate crushing effect is better, and through the capacity large.

9. Production capacity

When crushing soft mineral and weathered ore, the single cylinder hydraulic cone has the advantage of large passing capacity. But in the crushing medium-hard and high-hard ore, the performance of multi-cylinder is more outstanding. For example, more than medium-hard ore fine crushing, in the same specifications cone crusher machine, the multi-cylinder can produce more qualified products. The harder the stone, the greater the difference.

10. Maintenance

The single-cylinder has a simple structure and reliable performance. The advantages of this crusher are one hydraulic cylinder, simple and compact structure, low failure rate and low production cost. The simpler the mechanical system structure, the lower the failure rate, the higher the reliability and the more stable the operation.

The top or side of the multi-cylinder can be disassembled and repaired quickly and conveniently. All crusher parts can be disassembled and maintained from the top or side, the moving cone and the top cone are easy to disassemble. It doesn’t need to disassemble and assemble the frame, fastening bolts, and easy to replace daily.

Conclusion

The single-cylinder and multi-cylinder cone crushers are high-performance. The structure of the different so that each has its advantages and disadvantages. Compared with a single cylinder, multi-cylinder has more advantages of structural performance, maintenance, crushing efficiency, etc. Correspondingly, a multi-cylinder cone crusher price will be high, which may also be the user in the choice of the point that will focus on.

Warm Reminder

At present, there are some small multi cylinder hydraulic cone crushers manufacturers just make up from the charge of Simmons cone crusher. The spring changed into a hydraulic cylinder, but the internal structure is still the same.

Substantially, it still is Simmons crusher, users should pay attention when