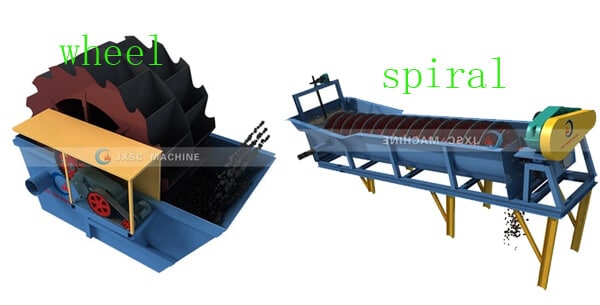

In the sand making process, if you want to obtain high-quality artificial sand, a wheel & spiral sand washing machine is essential equipment. Sand washing equipment is the final process of the manufactured sand production line. The equipment washing and screening for artificial sand, and get cleaner stone aggregate. The sand washing machine is widely used in quarry, mine, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station, and other industries. Wheel sand washing machine and spiral sand washing machine are two common sand washing equipment, what is the difference between them?

Sand Washing Machine Introduction

Wheel Sand Washing Machine

There are three types of wheel sand washing machine, divided into a single-wheel sand washing machine, double-wheel sand washing machine, three-wheel sand washing machine. When the machine operating, the motor drives the impeller through the belt pulley to rotate slowly. The material rolls and rubs under the rotation of the impeller. Then removes the impurities from the surface of the material. And destroy the water vapor coating on the sand particles to facilitate dehydration. At the same time, add water which forming a strong flow of water, take away the impurities and dust to complete the cleaning work.

The wheel type sand washing machine has the advantages of simple structure, less wearing parts, and small floor area. The impeller drive bearing device is isolated from water and water-receiving materials, which avoids bearing damage caused by water, sand and pollutants, and reduces the failure rate to a great extent. This type of sand washing machine is mainly used for cleaning stone powder, smaller particle size materials. It can realize the cleaning of the finished sand, the impurity removal, the dehydration, the removal of the excess sand with bad particles, etc.

Spiral Sand Washing Machine

Spiral sand washing machine equipment is relatively long. It adopts a horizontal structure, simple. But its installation arrangement is not as convenient as the wheel. This series of the sand washing machine can deal with stones less than 30mm. It mainly uses the different particle size and density of the material and the different settling velocity in the fluid to clean the material. In the operation of the equipment, the settling velocity of fine particles with small density is slow. The settling velocity of the particles with large size and density is fast. Through this characteristic, the dust, impurities, and sand can be effectively separated. The utility model achieves the purposes of water filtration, impurity removal and the like under the uniform stirring of the spiral slice.

Spiral sand washing machine processing capacity, large area, mainly used for fine and coarse materials impurities washing, classification, impurity removal, the role is classification.

Wheel VS Spiral Sand Waher

1. The water consumption is less in the wheel sand washing process, and the loss of fine sand and stone powder is small. The fine sand loss is larger in the spiral sand cleaning plant process. But sand relatively clean.

2. The capacity of wheel sand washing machine is under 80 tons. Therefore, it is suitable for the sand production line system with small and medium capacity. But the screw sand washing machine processing ability is big. It may carry on the effective cleaning operation to the muddy impurity serious sand. Often configured in a large-scale sand production line.

3. Price. Wheel sand washing machine price is relatively low, which belonging to the economic type of high-efficiency sand washing machine. It also has low operating costs. Spiral sand washing machine equipment prices are relatively high, belongs to high-end type of sand washing machine.

Sand Washing Process plant

According to the situation of sand and gravel, the wheel washing machine can be free to choose to add the number of grinding wheels. Therefore, the equipment has a single impeller sand washing machine, double impeller sand washing machine. Of course, you can also install a fine sand recovery device at the sand washer side.

If the sand and gravel material soil content is high or to increase production, the spiral sand washing machine can also increase the length or double spiral side-by-side. Therefore, there are single screw sand washing machine and double screw sand washing machine.

How choose

The output of the wheel sand washing machine is slightly lower. If the output requirements are not high, wash the fine aggregate, we can choose the wheel sand washing machine.

The spiral sand washing machine has high output, processing capacity strong, and its price is more expensive. If there is a high demand for output can be selected spiral sand washer.