One common fault of the belt conveyor is slipping. Once slipping occurs, it is easy to cause the phenomena of material dropping, feeding pipe blocking, belt wearing, belt breaking, etc. In this article, we analyze the 7 reasons for the slippage and the solutions.

1. Conveyor belt tension is insufficient

When the conveyor machine does not have enough tension. The driving wheel and transport belt will not have enough friction between the driving force. Then unable to traction conveyor belt and load movement. Screw or hydraulic tensioning device stroke is not enough or improper adjustment; Heavy hammer tensioning and vehicle tensioning device counterweight is not enough. The mechanism jam will cause the vibrating conveyor tension is not enough, resulting in slipping.

Solutions:

(1) screw conveyor and hydraulic belt conveyor can increase tension by adjusting the tensioning stroke.

(2) heavy duty belt conveyor and chain conveyor can via increasing additional weight and eliminating mechanism jam to solve. When adding the configuration of the tensioning device, no slipping is ok. And remember don’t add too much, otherwise, the belt conveyors will reduce service life because of bear unnecessary excessive tension.

2. Driving pulley encapsulation wear seriously

After the conveyor equipment has been running for a long time, the rubber surface of the driving drum and groove will be seriously worn. Which will reduce the friction coefficient and the friction force on the surface of the driving drum and cause the belt to slip.

Solution:

It should be taken to a re-coat or replace the drum method of treatment. Daily attention to the driving drum coating inspection.

3. the non-working face with attachment

Due to the change of natural environment, on-site ground flushing, equipment maintenance and other reasons, the non-working face of the conveyor belt has a certain lubricating effect of the attachment. When running, it will accumulate on the surface of the driving drum. Then causes between the drum and the conveyer belt friction to reduce obviously, causes the skid.

Solution:

The source of the attachment should be determined and the source cut off. If the source can not be cut off, you can sprinkle some rosin powder on the drum (blowing with a blower).

4. Conveyor belt overload

Due to improper operation or heavy-duty shutdown, conveyor equipment excessive load in the operation. It will result in the belt slippage.

Solution:

(1) Observe the electric current and electronic weigher of belt conveyor, and control the number of materials to avoid overload operation.

(2) Avoid heavy load downtime and overload as much as possible.

5. The blanking tube blocks

When the blanking pipe is blocked, a large amount of material will be piled up on the head and non-working face, crushing the conveyor belt and causing slipping.

Solution:

Pay attention to observe the change of the material on the belt. When the change of viscosity occurs, the inspection frequency of the blanking pipe should be increased, and the sticky material in the blanking pipe should be cleaned up in time to avoid clogging.

6. Scraping card

When the belt is partially blocked by the strong force, it will cause the belt conveyor to slip. For example, the mining conveyor belt head, the end of the blanking pipe card has foreign bodies, the tail direction of the drum does not rotate, and so on.

Solution:

Observe the conveyor current. It should immediately stop for inspection when the current abnormal change.

7. Friction coefficient too small

Usually between the driving wheel and the belt wrap angle should not be less than 120. Too small is easy to cause skidding. The friction coefficient too small also will cause the conveyor machine slip.

Solution:

When the cover angle between the driving wheel and the conveyor belt is low and the position of the adjusting tensioning wheel is effectively increased, the conveyor design should be modified. If the friction coefficient is too small, observe carefully whether the surface of the driving wheel is too smooth or not. Otherwise, it needs to adopt a knurling structure or inlay a layer of rubber and then test again.

What is conveyor belt

Belt conveyors are used in many important production units that require continuous operation, such as coal delivery in power plants, bulk material delivery in steel and cement plants. We know that it is not a good choice to shut down the machines. Using industrial conveyor belts can solve this trouble easily by working continuously.

Almost every step of the complete mineral processing circuit, mining, crushing, washing, beneficiation, drying, classification and so on, is connecting by the belt conveyor. JXSC conveyor belt is capable of operating heavy duty work even if under harsh conditions.

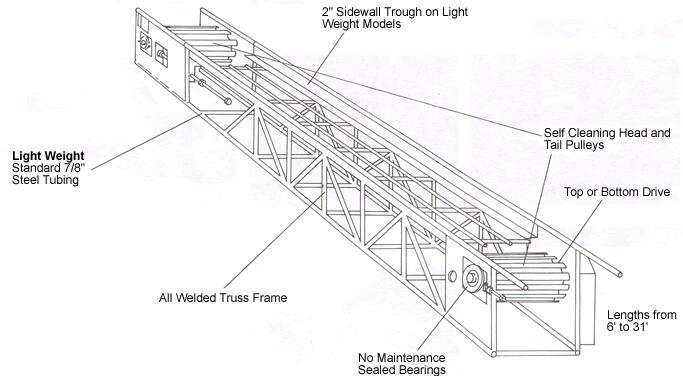

Conveyor parts: frame, support base, head pulley, carrying belt, belt roller, tensioning station, motor, etc.

Conveyor belt types

There is a great variety of belt conveyors. Such as roller conveyor, industrial belt, screw conveyor, chain conveyor, gravity roller conveyor, rubber belt, bucket conveyor, slat conveyor and more.

Conveyor belt for sale, JXSC is a conveyor belt manufacturers with 40 years of production and sales experience. If you want the conveyor belt price, please contact us.