Cobblestone is a stone formed after thousands of years of crustal movement and mountain torrential impact, it is famous for its shape familiar with a goose egg, and a pure natural sandstone material with a Mohs hardness of 7-8. The cobblestone has good compressive, wear-resistant, and corrosion-resistant and is the raw material for artificial sand.

Cobblestone crushed sand is also machine-made sand, with a particle size of less than 4.75mm and a reasonable grading, meeting the building sand standards. The experiments have shown that the sand crushed from cobblestone has the dual advantages of cobblestone and artificial sand, which improves the physical indicators of cement concrete and its crack resistance and achieves good technical, economic, and social benefits. The crushed cobblestone provide high-quality building materials for projects such as water conservancy and hydropower, high-grade highways, highways, high-speed railways, passenger dedicated lines, bridges, airport runways, municipal engineering, high-rise buildings, etc. Besides, they also provide raw and auxiliary materials for ceramics, precision casting, papermaking, spray grinding, chemical engineering, monocrystalline silicon, defense, etc. The reasonable design of the cobblestone sand production line brings good economic benefits and has high market and social value, with the increasing demand for cobblestone-made sand, more and more users are investing in cobblestone sand production lines. Let us take a look at the equipment for the cobblestone sand-making process.

Cobblestone Crushing Equipment

-

Cobblestone coarse crushing machine- jaw crusher

This type of cobblestone crusher is mainly for cobblestone primary crushing. Due to its high crushing ratio, simple structure, and low production cost investment, it is still relatively practical in the current cobblestone crushing process.

(1) It can crush all the materials in the crushing chamber cause the crushing chamber is deep, improving the crushing efficiency of the equipment and increasing the production capacity.

(2) The discharge port of the equipment is adjustable within the range of 10-400mm to meet users’ needs for material crushing.

(3) The crushed cobblestone particles are complete and uniform, with low needle-like content, which improves the efficiency of the equipment and reduces the pollution of dust to the environment during production.

-

Cobble crushing – cone crusher, hammer crusher, impact crusher

A cone crusher, hammer crusher, and impact crusher are for two-stage crushing, mainly used to complete the re-crushing operation of coarse materials. The difference is the cone crusher adopts the lamination principle and has a relatively ideal crushing effect on high-hardness materials. Compared to the impact crusher and hammer crusher, the wear-resistant parts have a longer service life, making them more suitable for the finely crushing operation of cobblestone. Besides, the cone crusher uses a bending and squeezing method to crush the cobblestone, resulting in a more uniform particle shape of the output, which is excellent. In addition, the cone crusher also has reliable safety. If non crushing objects such as iron blocks enter the machine, the iron protection device will automatically release them and then reset them to protect the machine and personnel. Therefore, regardless of the overall wear resistance strength, product particle shape, and operational safety, the cone crusher is superior to the hammer crusher and impact crusher.

3. Cobblestone sand crushing – VSI sand crusher machine

VSI sand-making machine is a sand-making machine for sand and gravel crushing. The sand-making machine has high sand-making efficiency, and the produced sand and gravel products have excellent particle shape and reasonable grading, which completely replaces natural sand and gravel in the current strict construction sand production to solve the problem of lacking natural sand and gravel. For users who have high requirements for the shape of the final product, investing in VSI sand-making machines is a wise choice.

(1) The design of the equipment is relatively reasonable, compact in structure, small in size, and light in weight, which facilitates the installation and operation of the equipment by users and reduces the occupied area of the equipment.

(2) The airflow automatically circulates inside the vortex chamber, with low noise. During operation, stones form a protective layer, and the body is free of wear, extending the service life of the equipment.

(3) For the vulnerable parts of the equipment, adopt hard materials to minimize wear and tear during operation, making the machine more durable.

-

Sand washing machine

The sand washing machine is an equipment for washing sand and gravel, which can effectively remove impurities covering the surface of sand and gravel, thereby meeting the production needs of users for materials, equipment used in sand and gravel factories, transportation, and concrete mixing stations to get great practical value.

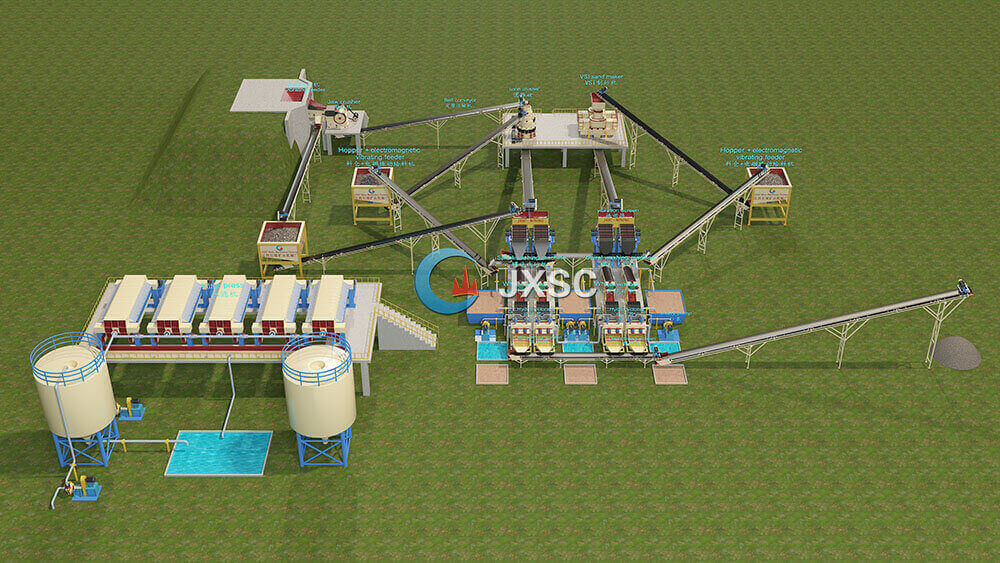

300tph Cobble Crushing Plant

This setup is a 300tph complete sand-making plant, max input size is 780mm, and output sizes are 0-5mm. It consists of a hopper, vibrating feeder DN5013, primary jaw crusher PE-900*1200, 2 sets cone crusher DN1800 sets vibrating screen, 2 sets VSI sand maker, and 12 pcs belt conveyors.

- The Excavator unloads the stones into the hopper, and the stone enters the vibrating feeder from the lower part of the hopper.

- The vibrating feeder feeds the 100-780mm stones evenly to the primary jaw crusher; the vibrating feeder is with a gap of 100mm grizzly bar. The 0-100mm stone will fall into the 1st belt, and goes to a transfer silo equipped with a hoist feeder, the material will be fed to the hopper above the 1st and 2nd vibrating screen by the 2nd conveyor belt.

- The output of 0-200mm of the jaw crusher will be transferred to the first set of the cone crusher by the 3rd conveyor.

- The output 0-35mm from the cone crusher will be sent to the 1st and 2nd vibrating screen to separate by the 4th conveyor. The size over 35mm stones will back to the 2nd cone crusher to crush through a 2nd transfer silo and 5th and 6th conveyors. 0-5mm sand will flow to the spiral sand washer to wash. 5-35mm sand will flow to the conveyor under the four vibrating screens. The conveyor will transfer it to the 3rd silo and then to 2 sets of VSI sand makers to crush till 0-5mm.

- The output material from the VSI sand maker will go to the silo above the 3rd, and 4th vibrating screens. The 0-5mm sand will flow to the spiral sand washer to wash. The +5 sand will flow to the underbelt and send back to the VSI sand maker to crush again.

- The output 0-5mm sand of each vibrating screen flow to the spiral sand washer and wheel sand washer to wash again, and then to the dewatering screen to dewater. After dewatering, get the final product.

- The tailings will be sent to 5 sets of filter press to press.

Throughout the entire sand production line, it is important to give full play to the advantages of each equipment and minimize equipment accumulation. If there is too much equipment in a production line, there will be other auxiliary equipment, increase costs, and affect economic benefits. Therefore, it is necessary to reasonably configure the production equipment for sand, and optimize and simplify the production process while meeting the production capacity requirements. JXSC Mine Machinery Factory provides all types of stone crushers and sand-making equipment, and all mining machines accept customization, come to inquire!