Both jaw crusher and gyratory crusher can be used as primary crusher. Jaw crushers are more widely used, probably because of their price. Except for the price difference, there are others different in the two types of crushers. Such as working principle, structure, applications, capacity, input/output particle size, etc. This article will analyze their differences in detail.

Working Principle

How jaw crusher works

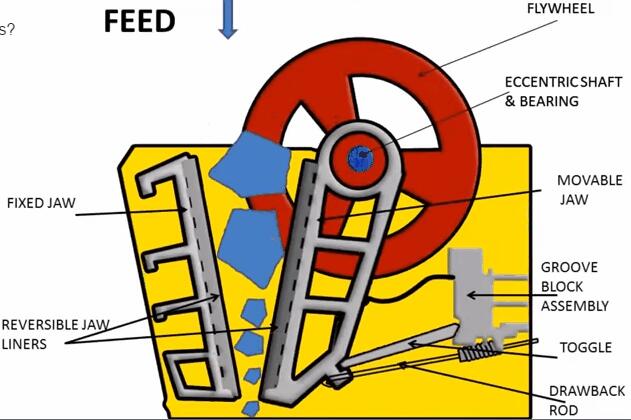

1. The crushing mode of the jaw crusher is a curved extrusion type. Its main working part is two jaw plates, fixed jaw plate (fixed jaw) and movable jaw plate (movable jaw). The crushing space is formed by the jaws.

2. The belt and pulley are driven by an electric motor to move the movable jaw up and down through an eccentric shaft when jaw crusher working. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, which pushes the movable jaw plate to approach the fixed jaw plate. When the movable jaw down, the angle between the toggle plate and the moving jaw becomes smaller. The movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring. The material enters the crushing chamber by gravity. The materials between the two jaw plates are crushed by extrusion, bending and cracking.

How gyratory crusher works

The crushing chamber of the gyratory crusher is composed of a moving cone and a fixed cone. When the crusher works, the motor passes the power to the horizontal shaft and a pair of bevel gears through the large and small pulley. The eccentric sleeve is connected with the big bevel gear and the moving cone places in the eccentric sleeve. By driving the eccentric sleeve to rotate, the moving cone rotates around the centerline of the crusher. Sometimes close to the crushing wall and sometimes leave, forcing the ore in the crushing chamber is constantly crushed and bent, then crushed.

Structure

The structure of the gyratory crusher is complex. The machine is tall and large, heavy and inconvenient to carry. It needs the higher factory building, the capital construction investment is big. The advantages of jaw crushers are a simple structure, low manufacturing cost, small, it is easy to configuration, convenient maintenance, etc.

Jaw crusher main parts:

- fixed jaw

- reversible jaw liners

- flywheel,

- eccentric shaft & bearing

- movable jaw

- groove block assembly

- toggle

- draw rod

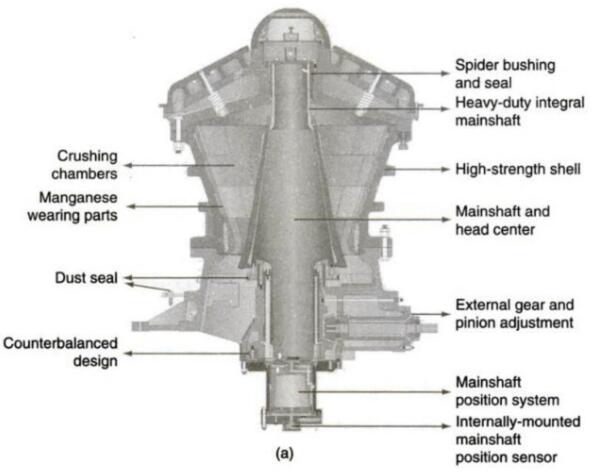

Gyratory crusher main parts:

- mainframe

- base

- concave liners

- mantle

- spider arm assembly

- drive assembly

- oil system.

Applications

The gyratory crusher is mainly used for coarse crushing various hard materials as primary crusher. But it is not suitable for crushing viscous materials. General the large-scale dressing mill uses gyratory crusher.

Jaw crusher can crush high moisture, viscous ore, and not easily blocked. General the small-scale dressing mill and quarry mostly use jaw crusher as primary coarse crushing.

Capacity

The gyratory crusher is continuous crushing. Its outstanding advantage is high productivity, the ratio of crushing is big, up to 6-9.5. Some of the crushing ratios can reach 13.5, and the work is smooth, vibration is small. Jaw crusher is intermittent crushing, crushing efficiency is relatively low. The feeding way is different, any side of the gyratory crusher can feed, and can be crowded to feed, high efficiency. Jaw crusher can’t be full feed.

Input/output particle size

The feeding size of the gyratory crusher is larger than the jaw crusher, and the output size is smaller and more uniform. The content of needle-like particles in discharge is less than 10%. The raw material can be poured from the conveyance directly into the feed port. It doesn’t need the feeder equipment.

The request of input particle size of the jaw crusher is strict. After blasting, it is necessary to impact and crush the big stone to meet the requirement of the coarse jaw crusher. In addition, the output of the coarse jaw crusher is mostly flat, sharp or triangular needle-like particles, the content of more than 20%. The product is not a good shape.

Useful life of wear parts

Jaw crusher is mainly used to impact the extrusion crushing principle. The jaw plate wears quickly, the maintenance quantity is big. The gyratory crusher adopts the principle of interlayer crushing. The crushing process is carried out continuously along with the circular crushing chamber, and the useful life of the wear parts is longer than the jaw crusher. For example, jaw crusher in normal use, the useful life of wear parts.

| Part | Useful life(month) | materials |

| Fixed jaw | 4 | High Mn steel |

| Movable jaw | 4 | High Mn steel |

| Sping | 6 | Spring steel |

| Bearing | 6 | Bearing steel |

| Toggle plate | 2 | Cast iron |

| Pull rod | 6 | straight carbon steel |

| Side plate | 4 | High Mn steel |

Energy consumption and cost

The average energy consumption of medium-sized gyratory crusher is much lower than the large and medium-sized jaw crusher. The crushing technology of the jaw crusher consumes high energy. The high energy consumption of coarse crushing process is mainly because the jaw crusher adopts discontinuous impact crushing. The single crusher has small productivity and needs to be equipped with many types of equipment. The main reason for high energy consumption in the medium and fine crushing process is that the coarse size is not uniform and the coarse material proportion is large, which increases the equipment load.

The high mining cost of the jaw crusher: ①the feeding size of the jaw crusher is small, which leads to the high density of drilling holes and the high consumption of explosive.②After blasting, there are a lot of big stone materials, and the workload of impact crushing is large.

Maintenance Cycle

Although the gyratory crusher price is high, its technology is advanced, long maintenance interval, low operating costs. But the daily operation and maintenance are more complicated than the jaw crusher.

Choose jaw crusher or gyratory crusher

The general large-scale crushing plant will choose the gyratory crusher as the primary crusher, except the viscous materials crusher plant. Because the capacity of the gyratory crusher is large, Big crushing ratio. The small mine crushing and quarries use jaw crusher.

If we consider the input/output particle size and production rate, when both crushers can reach the crushing requirement, it can choose according to the medium and fine crusher, investment, capital construction, environmental protection, etc.

When choosing, it can use jaw crusher, if a jaw crusher can meet the production requirements. If it needs two sets of jaw crusher, we can consider choosing a gyratory crusher.