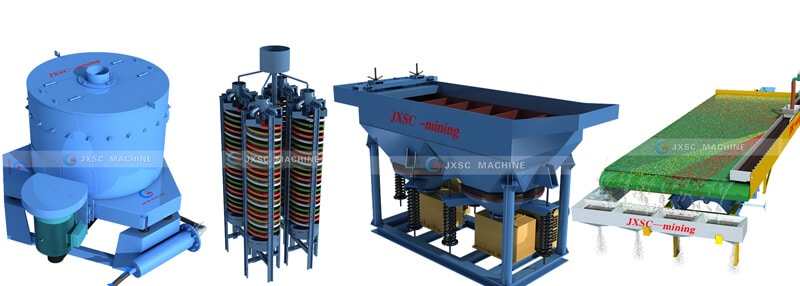

Gravity ore dressing/ gravity beneficiation/ gravity separation is one of the main ore beneficiation methods, includes heavy medium separation( DMS/ HMS), jigging, shaker concentrator, spiral chute concentrator. HMS and mineral jigs suit for the coarse ore particle, shaker has a high dressing accuracy, can be used in the weak magnetic iron mineral recovery plant, the spiral chute is very popular in the iron ore processing plant, besides, mineral centrifugal concentrators applied in the fine particle dressing. Specification of gravity separation method: low operating cost, little pollution. Main gravity separators machine as following.

1 Heavy medium separation

put crushed ore material into the heavy medium fluid( density greater than water’s), separate the two different materials under the flotation and sedimentation process of the buoyancy force.

HMS/ DMS has a good effect on the little density difference, thus a high separation accuracy. besides, large production capacity is also a great advantage.

heavy medium separation machines include a vibrating chute, ore dressing machine, cyclone, vortex, min particle low to 0.55mm.

2 Jigging separation

Chinese mining machine manufacturers can provide several types of jig concentrators like trapezoid jig, rectangular jig, Remer vibratory jig, hydraulic press jig, sawtooth Pulsation Jig, pan American jig, circular mineral jig, eccentric jig, plunger jig, duplex gold jigs, moving sieve jig, Harz jig, etc.

The working principle of the mineral jig: the ore particles in the jigging machine are mainly layered by means of the density differences, the bigger the gravity difference is, the higher the gravity separation efficiency is. it is necessary to keep layers with a certain shatter condition, if the material layer is very full and compaction, it will count against the jigging process, prolong the loose condition to improve the separation effect and capability.

3 Shaker

Generally, the particle size of ore dressing in the shaking table is in the range of 0.037 ~ 3 mm. in recent years, the shaker table as the ancillary equipment to recover the weak magnetic iron mineral. what’s more, shaking tables are widely used to separate tungsten, tin, niobium, tantalum and gold-bearing ores.

The shaking table surface is the working platform, the surface’s material types include wood, glass fiber reinforced polyester resin and aluminum alloy, shaker surface with a wear protection layer and providing corrosion resistant layer, greatly prolong the service life.

JXSC customer’s tin processing plant, 16 sets of shakers combine with the spiral separator, get a 60% tin concentrate.

4 Spiral Chute

Chute dressing machines include a spiral separator, spiral chute, vibrating chute, belt separator, centrifugal concentrator, etc. spiral separator is very popular in ore processing plants, meanwhile, an important and the widest used gravity separator machine.

4.1 Spiral separator mainly for coarse size ore, take Wabush iron ore dressing plant as an example.

Material: quartz-type weakly magnetic iron ore

Feed size: 0. 84 ~0mm

5 sets of spiral separators

Effect: original ore degree 35%, concentrate %64. Chinese ore dressing machine manufacturers start to develop spiral dressing equipment since 1950, practice shows that it has a good performance with 75.36% recovery rate( run mine 41%, concentrate 56%).

4.2 Centrifugal concentrator

We produce a fine particle cent concentrator for 0. 037 ~0. 010mm, I recent years, the gold centrifugal concentrator has a great development, plays a core role in the dressing plant of fine particle weak magnetic iron ore. Gold centrifuge combines with the chute, shaker improves the concentrate accuracy.

JXSC mining machinery factory provides gravity separator since 1985, contact us to know the latest price of gravity separator machine.