Impact crusher crushing capacity improvement

The impact crusher has a wide range of applications in mining production due to its simple structure, low price, good crushing particle shape, and convenient maintenance favorable for the separation of individual minerals (especially embedded minerals). In the mining crushing production line, the impact crusher is usually used as a secondary crusher that works with the vibrating feeder, vibrating screen, cone crusher, and jaw crusher to form a stone crushing line to crush the material to the required particle size. The production capacity of the impact crusher will directly affect the economic benefits of the entire production line. So, how can we effectively improve the production capacity of the impact crusher?

- Reasonably reduce the humidity of materials

If the material contains a large amount of water. It is easy for the material to adhere to the crushing chamber and block during the feeding process, reducing the production capacity of the impact crusher. Therefore, materials with high moisture content will adopt early drying or drying to lower the humidity of the materials.

- Pre screen materials in advance

If the material before crushing contains a large number of large blocks of ore. It will inevitably increase the crushing time of the material in the crushing chamber to lower the production capacity of the impact crusher. If the material contains a lot of fine powder before crushing, it will also reduce the production capacity of the impact crusher. Because these fine powders can easily adhere, affecting transportation and feeding. Pre-screening of materials in advance, screening out large and powdered materials for processing, makes the materials entering the crushing chamber more in line with the design requirements of impact crushing, effectively improving the production capacity of impact crushing.

- Reasonably increase the power of the motor

Within the rated motor power range, the larger the main motor power, the higher the production efficiency and capacity of the impact crusher. So, in production, it is possible to increase the power of the motor within the allowable range to increase the production capacity of the impact crusher.

- Increase the rotor speed appropriately

The rotational speed of the rotor is one of the working parameters of the impact crusher, which plays a decisive role in the production capacity, product particle size, and crushing ratio. Experiments have shown that the increase in impact crusher rotor speed will increase the production capacity and crushing ratio. The product particle size will also be relatively fine. With the increased speed of the rotor, power consumption increases, plate hammer wear accelerates, and the production costs will be higher. Therefore, in production, we cannot pursue a high rotor speed impact crusher, and the increase in speed should be appropriate.

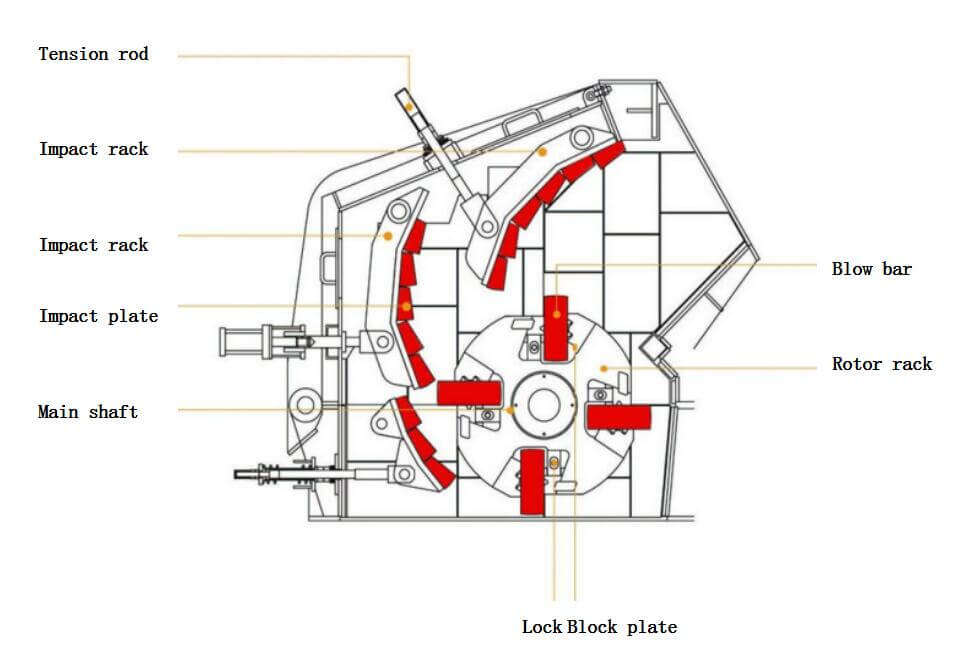

- The angle of the impact crusher plate should be appropriate

At present, there are line-shaped and arc-shaped impact plates in the market. The angle of each level of impact plate influences the effective crushing force generated by the material’s impact on the plate, which affects the impact and shear crushing effect of materials. Regular maintenance is essential to ensure the production efficiency of the impact crusher.

Impact crusher discharge particle size adjustment method

The impact crusher is a secondary crushing equipment on the sand making process plant, often working with a jaw crusher, which uses energy saving to crush materials. It is usually used to process materials with a hardness below medium and a particle size below 700mm and has various advantages.

The impact crusher has the advantages of good material particle shape and diverse crushing specifications after crushing. Due to its various adjustable methods for controlling the discharge particle shape and size. Below, we will introduce them in detail.

-

Adjusting the rotor speed

The impact crusher mainly relies on the impact energy of the high-speed rotation of the rotor to achieve mechanical crushing of the materials entering the crushing chamber. Therefore, adjusting the rotor speed will effectively control the discharge particle size.

-

Adjust the gap between the impact plate and the hammer plate

Adjusting the discharge gap to change the number of impacts on the material, thereby achieving the adjustment of material particle size. The methods of gap adjustment may vary depending on the type of equipment, mainly divided into two types of adjustment:

① Hydraulic adjustment

Equipment equipped with hydraulic devices can easily adjust this action through operating buttons or remote control systems. The spindle is located on the plunger inside the hydraulic cylinder, and changing the volume of hydraulic oil under the plunger can change the upper and lower positions of the crushing cone, thereby changing the discharge port size.

② Mechanical adjustment

This type of impact crusher is equipped with adjusting nuts above the main shaft of the equipment. By operating the adjusting nuts, the crushing cone is sufficient or rises, causing the discharge port to become larger or smaller.

Of course, depending on the model, there may be other ways to adjust the machine’s discharge size, as long as you follow the operating instructions.

The price of the stone crusher will determined by the manufacturer’s type, model, manufacturing process capacity, etc. We can provide various mining equipment like stone crushers, etc. Welcome to consult JXSC‘s professional engineers to get the quotation based on your requirements. We will design a sand-making and crushing production line flow chart for you.