In the Mineral Processing Plant, due to the influence of geographical climate and surrounding chemical media, mechanical equipment inevitably has corrosion problems. The material, time of use and environmental adaptability of the parts of the mineral processing equipment directly affect the performance of the equipment. Conduct on-site investigation on the wearing parts, corrosive parts and working conditions of mineral processing plant, understand the corrosion behavior and corrosion influencing factors of mineral processing equipment components, and deeply understand the environmental adaptability of mineral machinery equipment, and improve the wearing parts of mineral machinery equipment. The key to the level of materials used for corrosive parts, prolonging service life and enhancing equipment reliability. Combined with the working principle and structural characteristics of the equipment, analysis four main easy to corrosive equipments such as cone crusher, vibrating screen, ball mill and flotation machine, determine the main corrosion types and corresponding Protective measures.

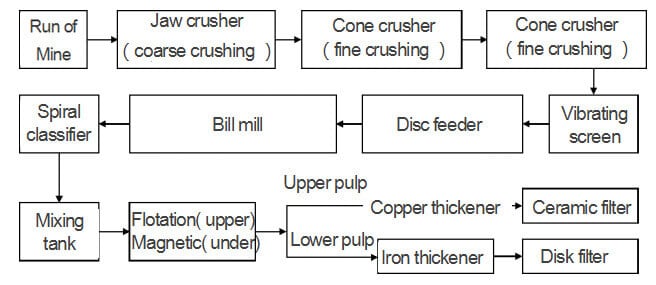

1 Mineral processing flow

main miner process equipment includes jaw crusher, cone crusher, spiral classifier, ball mill, disc feeder, vibrating screen, mixing tank, flotation, magnetic separation, thickener, filter.

2 Cone crusher

2.1 Cone crusher working principle and structure

The conical crusher consists of a frame, an upper broken wall (fixed cone), a lower broken wall (moving cone), a horizontal shaft, a balance wheel, an eccentric bushing, a fluid coupling, a lubrication system, a hydraulic system, a control system, and the like. The cone crusher is used to break ore and rock with medium and medium hardness. During the work, the broken cone is rotated around the main shaft for rotation, so that the distance between the broken wall of the cone crusher and the fixed installation of the rolling wall is repeatedly moved, causing the ore to be subjected to impact, bending and extrusion of the two cones in the crushing chamber. The rolling and crushing walls that are in direct contact with the material are required to withstand relatively high wear resistance and impact toughness. The lining plate is prone to severe wear and tear due to strong impact, and the replacement of the lining plate takes a long time, which seriously affects the production schedule.

2.2 Main wear parts

Broken wall, rolling wall, distribution tray, backing material, oil pump, body armor, guard plate, gear, motor, taper sleeve, eccentric shaft, bearing, etc. as important components of cone crusher, also cone crusher Damaged parts in the mineral processing plant. On-site investigation found that the bearing corrosion of the cone crusher is serious, and obvious rust marks can be observed. Bearings tend to accumulate water, deposit sand and iron filings, and bear large loads, which can lead to corrosion of bearings. damage. Corrosion on the outside of the rolling mill wall of the cone crusher is serious, and obvious erosion, groove-like traces and local corrosion pits can be observed.

2.3 Consumable parts failure reason

The mine cone crusher is generally dry except for the rainy season and the relative humidity of the equipment itself. Corrosion of cone crusher is mainly caused by severe impact wear, collision wear and abrasive wear, accompanied by pit erosion, pitting corrosion, erosion corrosion and between bolt and nut screw, between bolt and equipment outer wall, equipment inner wall and metal ore. The local corrosion and wear between galvanic corrosion promote each other. Therefore, the failure mechanism is mainly the combination of abrasive wear, impact wear, collision wear and corrosion wear. Among them, corrosion promotes wear, impact wear includes impact, Collision and abrasive wear patterns are the most important causes of material abrasion failure.

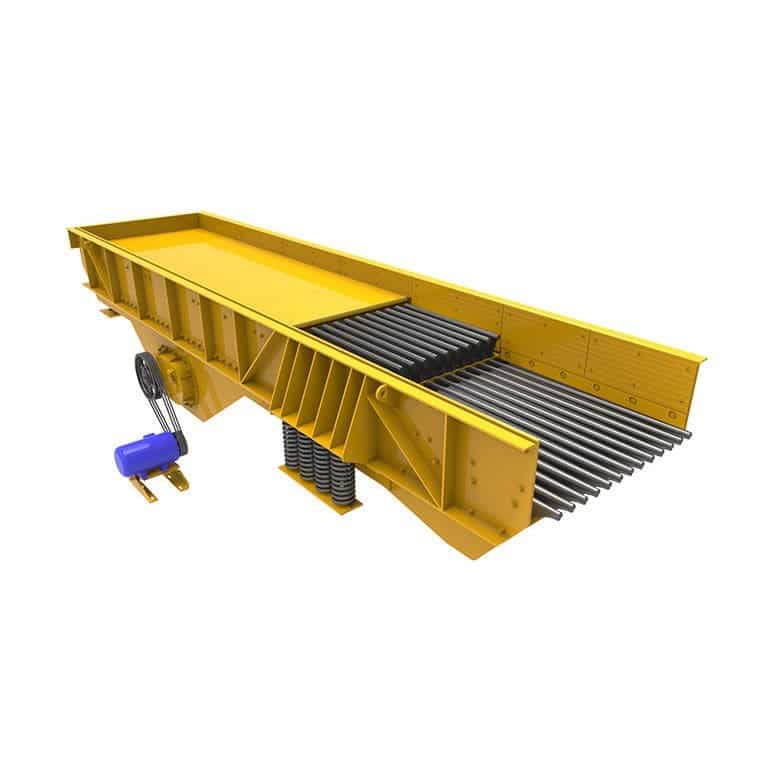

3 Vibrating screen

3.1 Vibrating screen working principle and structure

Vibrating screen consists of frame, spring, sieve body, sieve plate, screen box, screen, feed plate, discharge plate, beam drive shaft and non-body excitation system (vibrator), support device (base frame) , transmission, motor bracket. The double deck vibrating screen relies on the porous working faces of the two vibrating screens to classify the ore particles. The mine uses a horizontal linear inertial vibrating screen that stimulates the ore particles on the screen surface to move well. The horizontal linear inertial vibrating screen has different layers (2~4 layers), and the screen has relatively uniform force, which is especially suitable for material classification. The life of a linear vibrating screen is longer than that of a circular or elliptical vibrating screen.

3.2 Main wear parts

The vibrating screen is placed between the medium crushing cone crusher and the fine crushing cone crusher in the mineral processing plant. The entire beneficiation chamber where the vibrating screen is located is vibrated under the influence of high frequency and high vibration of the vibrating feeder and the vibrating screening machine. The equipment in the service environment It is prone to environmental fatigue and the screening environment is dusty. The continuous high-frequency vibration force will cause the sieve of the vibrating screen to fatigue fracture of the frame weld and the working condition of the vibrating bearing is more severe than the general transmission bearing. The inner wall of the funnel is seriously corroded under the influence of friction and wear of the vibrating abrasive. The outer wall of the funnel is affected by long-term vibration, and it is easy to fail due to fatigue under the acceleration of the vibration and wear of the inner wall. Therefore, the vibrating screen has a short service life and the highest maintenance frequency.

The failure of the vibrating screen is as follows: the sieve hole is easily blocked, the sieve body is easy to deform, the screen plate is vibrating friction and wear, the cross beam is broken, and the side plate is cracked. Vibration wear and fatigue damage, weld cracking and other damage of vibration bearing. The damage caused by corrosion is mainly caused by vibration bearing, sieve plate, screen, spring, screw, nut, etc.

4 Ball mill

4.1 Ball mill working principle and structure

The ball mill is made up of the barrel part (liner, partition board, end cover, grinding ball), the ore part, the mining department (lattice lining), the bearing part (inlet and outlet bearing), the transmission system (transmission large, small gear ) and lubrication system. The ball mill drives the cylindrical device to rotate the ball mill through the large and small gear transmissions, and feeds the qualified ore particles after sieving and fine crushing to the mining machine. The ball milled pulp is discharged to the discharge port through the lattice liner to enter the next section. The cyclical movement of the grinding ball rising and falling is repeated, and the grinding action between the lining plate, the grinding ball and the material makes the ore particles fine.

4.2 Main wear parts

liners, grinding balls, lifting bars, screws, transmission pinions, etc. are the most corrosion and wear parts of ball mill, especially in the wet type ball mill.

5 Flotation machine

5.1 Flotation machine working principle and structure

The flotation machine is mainly used as a screening device for the grinding and floating section, for flotation process quality is directly decisive. The grinding and floating section of the mine adopts a flotation machine bundled with the magnetic separator, the flotation machine is on, the magnetic separator is on the bottom, and the copper concentrate is scraped off by the scraper conveyor. The iron slurry is absorbed by the magnetic separator. The iron ore slurry is directly Enter the iron selection section.

5.2 Main wear parts

Flotation cell of flotation machine is immersed in flotation reagent and pulp for a long time, the groove wall is prone to corrosion and wear damage.

6 Protection measurement

6.1 Cone crusher

(1) For corrosive materials such as acid and alkali, enter the crusher

It was previously treated with acid reduction and alkali reduction.

(2) Regular maintenance and repair, such as checking the lining of the lining, breaking

Wear of wearing parts such as broken walls, and found that serious wear parts are timely

replace.

(3) Improvement of the structure of the crusher, such as adding a fixed guard to the fuselage to reduce the frequent disassembly and installation of the spherical tile and the tile seat;

Pre-buried low carbon steel plate on the board, so that wear first occurs at a lower hardness

On carbon steel, the lining only forms shallow grooves on the surface.

(4) Special design or corrosion-resistant materials for corrosive parts

6.2 Vibrating screen

(1) The sieve body is made of materials with stronger fatigue resistance and corrosion resistance; in the process of processing, high-pressure water gun and laser cutting technology are used to avoid stress concentration; the screen frame parts are treated with anti-corrosion treatment.

(2) Select the wear-resistant coating for coating according to the working conditions. The thickness of the coating should be selected according to the working conditions.

(3) The aging treatment technique is used to remove the bending or welding stress of the member. According to statistics, 20% to 60% of the internal stress can be removed.

(4) The sieve plate parts are fixed by the snap ring, which can further disperse the stress condition and avoid the fatigue fracture of the beam.

(5) Using a welded screen to develop a non-metallic screen surface to reduce the occurrence of screening process failures and improve the screening effect and screen life.

(6) Replace the welding by riveting to avoid the occurrence of open welding and fatigue fracture of the screen frame weld.

6.3 Ball mill

(1) Select grinding balls with high wear resistance and good quality stability, such as low-chromium white cast iron grinding balls, low in price and stable in quality, in metal ore

Mountain application is cost-effective.

(2) Develop long-life low-carbon and high-alloy new liner materials to replace traditional high-manganese steel; Reasonably select high-efficiency new steel grades to improve the life of ball mill liners and reduce production costs.

(3) Regularly clean the grinding balls in the cylinder, remove the broken and lost balls, reconfigure the proportion of grinding balls of various sizes, and improve the grinding efficiency.

(4) Improve the process. According to the research, nitrogen filling in the ball mill can reduce the wear loss of high carbon low alloy steel by 25%. The electrochemical method can reduce the corrosion loss of the ball mill liner.

6.4 Flotation

(1) The entire surface of the flotation equipment body is painted and protected to reduce the corrosion of the fuselage and to carry out daily maintenance and maintenance.

(2) Improve the working environment of the flotation machine, such as adding corrosion inhibitor to the flotation medium to reduce the corrosion rate of the equipment.

(3) When the flotation machine is working, the coarse ore particles larger than 0.5 mm are restricted to enter the flotation machine, and the ore is periodically discharged from the bottom of the tank to avoid large particles entering due to reasons such as “running rough”.

(4) Regularly repair or replace the impeller of the core component of the flotation machine, and adjust the gap between the impeller and the stator to be between 6 and 10 mm. To avoid the rust and accelerate the impeller wear, the flotation machine will stop for a long time. It is necessary to vent the slurry in the tank; develop non-metallic impellers, such as using polyurethane instead of cast iron to make the impeller, the life can be increased by 5 to 7 times.

(5) During the long-term strong rotation of the slurry of the flotation machine, the protective plate will be deformed, the groove body will become thin and leak, and the wear-deformed groove body and the plate should be repaired in time. If the damage is serious, the whole plate should be replaced.

JXSC is a 30+ years of mining equipment suppliers, our mining machine, coal mining equipment are widely use in the mineral processing plants.