What sand washing wastewater

Sand washing wastewater refers to the wastewater produced by the sand washing plant. Aggregate is one of the basic building materials. With the increasing demand for sand in global, natural sand is facing the pressure of resource reduction and environmental protection. Artificial sand will be an important source of construction sand in the building materials market.

Manufactured sand is widely used in concrete, mortar, and products. It shows more and more good market prospects in modern construction projects. The gradual replacement of natural sand in quality and quantity is one of the signs that the artificial sand production line has entered a new period of development.

Characteristics of wastewater

The main pollution factors of sand wastewater are chemical oxygen demand and suspended matter. The highest concentration of suspended matter is about 3000 mg / L, forming a large amount of mud water. The characteristics of the mud depend on its composition and are related to the local geological conditions. The general characteristics are that the mud looks like earth yellow, uniformly sticky. It remains at rest for a long time without layering. Its specific gravity ranges from 1.20 to 1.46(of which the specific gravity of yellow sand is 1.6). The mud content ranges from 20% to 30% Ph: 6 ~ 7.

Before the comprehensive treatment of wastewater, the annual volume of wastewater produced is 80,000 tons (in this case, one mill) at the rate of 8 hours per day, 25 days per month and 10 months per year. The wastewater contains about 80 tons of chemical oxygen demand and 8,000 tons of suspended matter (SS). If it is not treated in a timely and effective manner, it will not only waste a lot of water resources but also pollute water quality and affect road traffic. And it will affect the normal production and life of nearby residents and even intensify social contradictions. And adding disharmony factors to society.

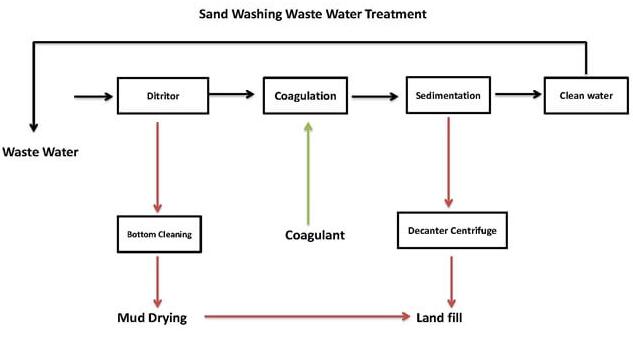

Treatment methods

The treatment method is nothing more than the separation of mud and water. The mud and sand are separated by physical methods. As the sand content of the wastewater is large, the fine sand is first settled by natural sedimentation in the primary sedimentation tank. In order to reduce the cost of chemicals by controlling the solid content in the process of adding flocculants. Adding the flocculants to form particles. The supernatant is reused in the clear water tank, and the sludge in the lower layer is put into the sludge dewatering equipment. Disposal of mud cake by external transportation.

Sand Washing Method

1. Wheel sand washing machine

The raw material goes into a wheel sand washing machine through the hopper for pre-screening. During the sand screening process, the sand from the vibrating screen feeds into the sand washer equipment through the bottom feed intake of the machine. The sieved big particles discharge pass through the big material outlet of the cylinder screen. Then waiting for the customer to further deal with.

2. Spiral sand washing machine

The crushed sand entering the spiral sand washing machine is continuously stirred, rubbed and rubbed against each other under the action of the rotating stranding dragon. So as to achieve the separation of soil and sand cleaning effect. In the sand washing process, the sewage produced by dissolving the soil in water is discharged through the discharge port of the screw sand washing machine. And it is discharged through the sewage canal to the three-stage sedimentation tank for the purpose of recycling.

The sand which has been cleaned by the spiral sand washing machine is pushed into the sand washing machine again by the cutter for the second cleaning operation. Its purpose is to clean the sand better. JXSC recommends installing the spray clean water device in the discharge end of the sand washer for cleaning operations again.

JXSC sand washing plant

The sand washing production line designed by our company not only has a screening process but also has two cleaning processes. Pre-screening not only separates the big pieces of material and the excessive fine powder in advance. It is convenient for users to make sand from big materials. And also effectively reduce the pressure of the follow-up sand washing equipment, increasing the output of the whole production line. Extend the later period of settling tank cleaning, significantly increasing the economic benefits of users.

Our sand washing plant is not only suitable for cleaning mountain sand, but also suitable for washing stone powder sand, river sand, earthwork sand, and sea sand desalination operations. Customers who need more detailed information can contact us directly by phone. We will recommend the most suitable equipment and sand cleaning process as well as site planning and layout according to your raw material situation, your requirements and site limitation. Sand making machine, sand washing machine, vibrating screen, belt conveyor, Chine stone crusher plant machine and sand plant equipment for sale.