Mobile crusher plant is the core equipment of continuous and semi-continuous mining technology in an open-pit mine. It is responsible for the primary crusher of raw coal transported by truck or loader, and transferring to the belt conveyor or loader. The reloading machine is a bridge connecting the mobile crushing station and the belt conveyor. By adjusting its position, the raw coal on the mobile crushing plant can be transferred to the fixed belt conveyor continuously.

The open-pit mine mobile crusher plant is the key equipment for mining. The mobile crushing plant is the result of the development of open-pit mining. Compared with other types of crushing plants, it has the advantages of flexible movement, high crushing ratio, low energy consumption, high output and low transportation cost. The advantages are more outstanding when mining in deep sunken open pit mine.

With the rapid development of modern mine technology, higher requirements are put forward for the equipment level and systematic arrangement of the mobile crusher machine. The crusher plant is mainly composed of rock crusher, vibrating feeder and belt conveyor. The plant adds he active or passive moving base on its basis, and the structure is adapted to move.

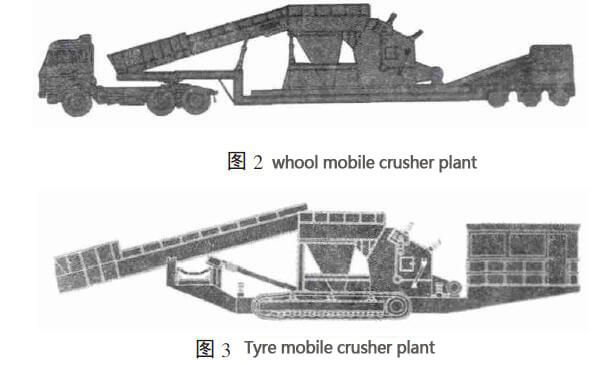

The types of mobile crusher: wheel mobile crusher and tyre mobile crusher.

The structural form of crushing station

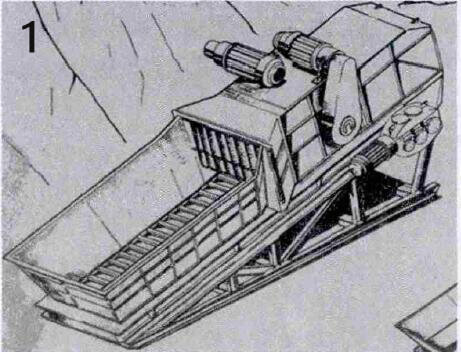

1) Mobile hammer crusher plant

The rotor is the main working part of the hammer crusher, it is rotating at high-speed in the stone crusher. The Hammer is the main component of the rotor. The material enters the crusher equipment from the feeding opening, and crushed under the impact and grinding of the hammer. There is a screen plate set the lower part of the crusher machine, the materials which meet the crushing requirements were discharged by vibrating screen. Hammer crushing plant as shown in figure 1.

The advantages of hammer crusher: simple structure, equipment with lightweight and big capacity, big crushing ratio, easy to maintain, etc.

The disadvantages of the Hammer crusher: the hammer and the grate screen wear fast, overhaul time is long. If crushing hard material, the parts of crusher wear faster; When crushing sticky wet material, easy to plug the grate screen seam, cause machine halt.

2) Mobile Impact crusher plant

The impact crusher mainly uses the impact principle to crush the material. The board hammer and the impact device are the main working parts of the impact crushers. The plate hammer is made of high manganese steel or other wear-resisting alloy steel. And the shape of the plate hammer is generally long strip. The anti-impact device is also with a wear-resistant lining plate, which is made into the shape of a broken line and arc, so achieve the best crushing effect of coal.

During working, the raw material enters the working area of the hammer from the feed hole, the hammer hits the material. Then the material is thrown onto the counterattack device to be secondly crusher, and the material is broken repeatedly by the impact between the hammer and the impact device. The impact crusher has 3 impact chambers, the materials enter these 3 impact chambers in turn for repeated crushing until the material is crushed to the required size, and discharged from the outlet of the crusher. The impact crusher equipment can adjust the gap size between the impact frame and the rotor to adjust the size of the need. Impact crusher plant as shown in figure 2, figure 3.

The advantages of the impact crusher: it put the ways of strike, impact and grinding with a good combination. High crushing efficiency, uniform particle size, easy maintenance and low energy consumption.

Compared with the hammer crusher, the impact crusher machine can better control the particle size of the crushed materials, and can well break the fragmented or strip material. In order to avoid the small pieces of material into the crusher is crushed too small, usually installed a screening machine between the chain conveyor and crusher equipment. The screened small piece of material and the crushed material are transported on the discharge belt conveyor at the same time. Due to the limitation of mass and volume, the impact crusher is difficult to develop to large scale, and has no advantage compared with the tooth roll crusher.

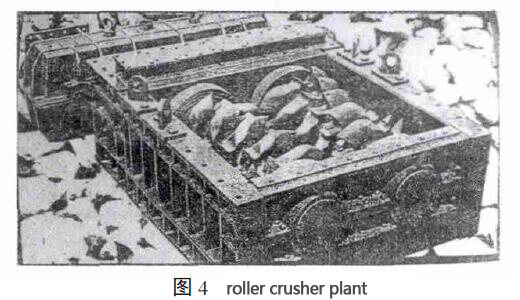

3) Mobile tooth crusher plant.

Tooth crusher also is known as roller crusher, the common use of two-roll is the double roller crusher. It uses two rotating cylindrical rollers, using the principle of extrusion and grinding to achieve the purpose of crushing. When the material reaches the required size discharge from between the two rollers. According to the number of rolls, roll shape. roller crusher is divided into single-roller, double-roller, double-stick three-section, double-stick four-section, smooth surface roller machine and tooth surface roller machine. Tooth crusher equipment as shown in figure 4.

The roller tooth crusher has the advantages of compact structure, reliable operation and convenient adjustment of crushing ratio.

The Mobile roller crusher plant is usually composed of roller crusher and belt conveyor. materials are usually directly dumped on the crusher by trucks or loaders. The feeder size of the roller crusher is larger than the first two , so it is not easy to cause a blockage. The discharging opening is also very large, almost the whole lower part of the machine is discharging the broken material.

Types of stone crusher

According to the main force nature of crushing materials, crusher machine can be divided into extrusion-type, impact-type, and shear-type.

1) Extrusion crusher

Including the cone crusher, jaw crusher, smooth surface or groove tooth surface of the roller crusher, etc. They depended on the grinding action to work. When the crusher works, it must exert a very large crushing force on the material, so the machine is heavy, with low efficiency and high energy consumption.

2) Impact crusher

Including the impact crusher, hammer crusher and so on. Impact crusher due to high-speed rotation of the crushing shaft, hammer and materials, impact plate and materials high-speed impact, and then produce strong wear and tear.

3) Shearing crusher

Its working principle is based on the direct action of the shearing force on the material. The force along the weak and friable parts of the material to generate a huge crushing force to crush it.

In short, roller crusher plant compact structure, high production capacity, good adaptability to materials, is the ideal mining equipment for large open-pit mines. But this machine also exists the problem of complicated structure and high price.

Although the structure of the mobile hammer crushing plant is falling behind, the maximum production capacity it can reach is much smaller than roller crusher, but the system crushing station has a high similarity with the existing products of the underground crusher and reloaders. The reducer, sprocket shaft group, crusher shaft group and other key parts to achieve universal design and manufacturing, so the hammer crusher price and structural has obvious advantages.