Artificial Sand Making Plant and Machine

When it comes to barren rock, do you think of a waste rock yard, which not only occupies a large amount of cultivated land, but also needs to pay a large amount of land occupation fees for this, and there is a danger of landslides and mudslides at any time. However, if the waste rock is processed into the sandstone that is needed for urban construction, it not only solves the problem of waste rock discharge, but also provides high-quality and low-priced raw materials for the sand and gravel industry, and achieves a win-win situation for economic benefits. Why not!

use mine barren rock to process gravel aggregate sand

Recently, writer learned about the great example who cement producer use mine waste rock to process artificial sand and gravel materials.

1 Description of barren rock site

Main material: low-grade limestone and dolomite, little clay.

Particle size: uneven size, the large diameter is more than 2m. It is necessary to use an excavator with a hammer to crush into 800mm or less.

2 The capacity of artificial sand making plant

The waste rock displacement is 2000-3000t/d. Considering the market demand, investment scale and production site, it is decided to build a mine waste stone artificial sandstone production line with a production scale of 200t/h and a daily output (working 16h) of 3000t/d.

3 Artificial sand making line design

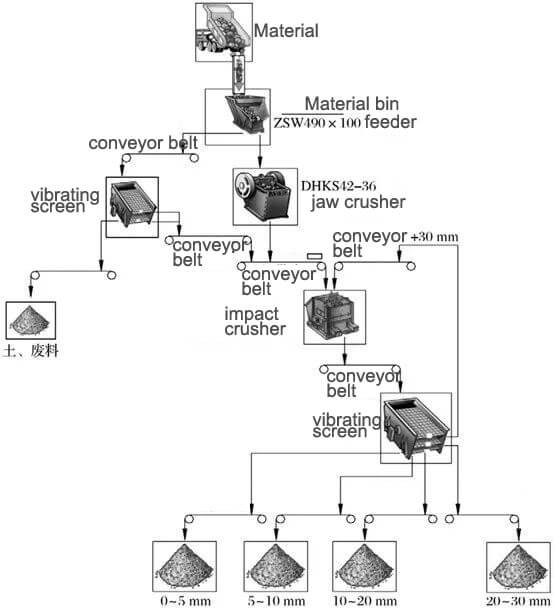

Aggregate processing procedure: firstly, crush material into 800mm, load in the material bin, put a 800mm×800mm sieve upper the material discard mouth.

Below the raw material warehouse, there is a rod vibrating feeding screen, and the soil and small waste rock smaller than the rod screen mesh are sent to the soil removing screen by the No. 1 belt conveyor for screening, which is smaller than the vibrating screen (20 mm). Most of them are soil and weathered waste rock, which can not be used as building aggregate, but can be used as cushion material for highway subgrade; waste stone larger than sieve hole (20mm) is returned to No. 3 belt by No. 2 belt conveyor The conveyor is sent to the suspended iron remover together with the ore crushed by the jaw crusher. The iron ore after the iron removal enters the counter crusher for crushing, and the crushed material is transported by the No. 4 belt conveyor. The 4-layer vibrating screen is screened, and the raw material (+30mm) larger than the upper screen mesh hole is returned to the counter crusher by the 5th belt conveyor and then broken, forming a closed loop with the vibrating screen.

After sieving through a vibrating screen, four finished materials of 0 to 5 mm, 5 to 10 mm, 10 to 20 mm, and 20 to 30 mm are obtained.

4 Artificial sand manufacturing machine

The coarse crushing machine adopts DHKS4236 jaw crusher. Its feed opening is 920mm wide and 1060mm long. It can meet the requirements of maximum feeding 800mm, discharge opening size 150mm and production capacity of 250t/h. After coarse crushing by the jaw crusher, the ore is removed by a suspended iron remover to remove large pieces of magnetic unbreakable objects such as drill bits and shovel heads, preventing unbreakable objects from entering the secondary crusher chamber and damaging the host.

The second-stage crushing adopts PFQ1315 type impact crusher, the maximum feed size can reach 600mm, the product shape is cubic, and the gradation is reasonable.

The 4YKR2460 vibrating screen was used for grading screening.

5 Dust removal and noise reduction system

According to the experience of nearby stone factories, dry bag filters are not effective. After a comparison of various dust removal schemes, it was decided to adopt a simple and practical spray dust removal method. A high-level pool is arranged near the raw material storage tank, and the water in the water pool is distributed to the silo, the jaw crusher, the impact crusher, the vibrating screen discharge port and the finished material belt conveyor head through the pipeline to carry out the mist spray. The amount of water spray is adjustable.

6 Using effect

After the formal production, the actual production capacity exceeds the design capacity by 20%, reaching 240t/h. The granular shape of the finished material is cubic, the content of the needle is very small, and the gradation is reasonable, which fully meets the requirements of various indexes for sandstone materials for urban construction and expressway. The water consumption of spray dust removal is 6~10t/h, and the dust removal effect is good. The moisture content of the finished product is about 3% to 5%, and almost no dust is generated during the transportation and loading and unloading process of the automobile. All investment can be recovered within half a year of normal production. Pumps for sale – Walker pump

7 Conclusion

The artificial sand making plant has the characteristics of a low investment, large production capacity and quick effect; its spray dust removal system is simple and practical; it can process the waste rock into various building aggregates that meet the requirements of buildings and expressways, and save energy and reduce emissions for mines. Turning waste into treasure and comprehensive utilization provide a successful experience and it is worth promoting and applying.

JXSC provide sand making machine, sand washing machine, rock crusher, conveyor belt, etc. for over 30 years, contact us to get the latest sand making machine price.