Natural gypsum goes through crushing, grinding, and calcining to become gypsum powder. It is one of the five gel materials used in many fields, such as architecture, building materials, industrial molds, art models, the chemical industry and agriculture, food processing, medicine, and beauty industry. It is an important industrial raw material.

The color of gypsum powder is generally white and transparent and sometimes becomes gray, light yellow, or light brown due to impurities and residues. Gypsum powder has a wide application, good market prospects, simple processing technology, and reasonable prices. In addition, gypsum products have the characteristic of green environmental protection, energy conservation, and lightweight, so many people choose to invest in gypsum powder production lines.

Application

- Making cement retarder: Gypsum powder is an indispensable additive in the concrete industry, often used as a Portland cement retarder added to building concrete.

- Used for building decoration: Gypsum powder is used for wall laying, pointing joints, and wall leveling in building decoration. The main component is gypsum powder. Some colored gypsum powder also plays a decorative role at a low cost.

- Product gypsum-type building materials: such as fiber gypsum board, plastering gypsum, gypsum powder, gypsum mortar, gypsum partition board, paper gypsum board, plastering gypsum, building standard bricks, etc.

Gypsum Powder Processing

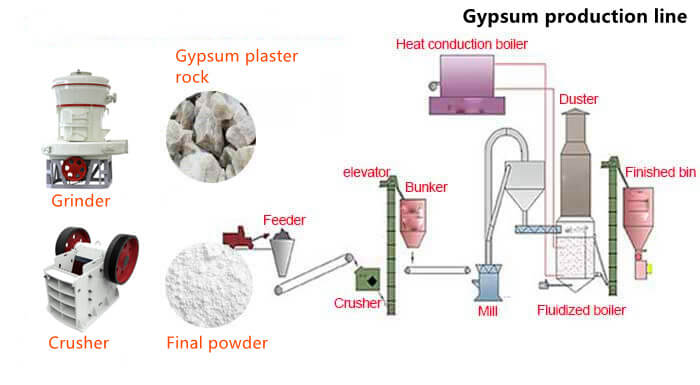

What is the process of gypsum powder? Usually, gypsum powder production lines have crushing systems, grinding systems, calcination systems, storage and transportation systems, and electrical control systems, among which the crushing and grinding systems are two key steps.

- Crushing system: gypsum raw materials enter the crusher machine through a vibrating feeder for crushing large-size gypsum ore into small particles smaller than 30mm for backup. According to the size of gypsum raw materials and different production requirements, corresponding specifications to select the crusher, usually include jaw crushers, hammer crushers, or impact crushers. In order to protect the environment, gypsum crushing and grinding machines equipped with dust removal equipment are good ways to meet environmental emission requirements.

- Grinding system: Materials uniformly and continuously feed into the grinding mill through an electromagnetic vibrating feeder. After grinding, the raw gypsum powder is blown out by the airflow and graded by the Analytical engine above the host machine. The powder with the specified fineness enters the cyclone collector with the airflow and is collected and discharged through the powder discharge pipe to form the finished product. The finished product falls into the screw conveyor and transport to the next system for calcination. The entire air duct system is a closed loop system, with a bag filter introduced from the pipeline between the cyclone collector and the blower to remove dust from the air, and then discharged into the air to ensure cleanliness. The material passing through the grinding system changes from a particle size of 0-30mm to 80-120 mesh, which meets the fineness requirements of gypsum powder.

- Gypsum Grinding Machine

A gypsum grinding machine is a specialized grinding equipment developed based on the unique properties of gypsum. The gypsum mill is suitable for processing a wide range of materials, as many as 280 kinds, ranging from Mohs scale hardness of 9.3 to nonflammable and explosive materials with humidity below 6%. Specifically, it includes Baryte, Calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, lime, active clay, active carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass, thermal insulation materials, etc.

Working principle

- During operation, large pieces of material are crushed into small particles by a jaw crusher or hammer crusher, then sent to the storage bin by a hoist. The electromagnetic vibration feeder evenly delivers the material to the middle of the upper rotary table. The main motor of the host drives the spindle and various layers of rotary tables to rotate through a reducer, and the rotary table drive dozens of ring rollers to roll and rotate in the grinding ring raceway through a circular shaft pin.

- Under the action of centrifugal force, the material disperses towards the periphery of the circle and falls into the rolling path of the grinding ring, stamping, rolling, grinding by the ring roller, and crushed to powder. The material is crushed layer by layer and then falls into the second and third layers. The external air sucks into the machine through the suction of a high-pressure centrifugal fan, and the crushed material from the third layer bring into the powder separator.

- The rotating worm wheel inside the powder concentrator causes the coarse material to fall back and regrind, while the fine powder enters the cyclone dust collector with the airflow and discharged by the discharge valve at the bottom to form the finished product. The airflow with a small amount of fine dust is purified by a pulse dust collector and discharged through a fan and muffler.

Advantages

- The finished product of the gypsum grinding machine has uniform particle size, good particle shape, and a high screening rate, which meets the actual production needs of users.

- The grinding rollers and other configurations of the gypsum grinding machine are made of wear-resistant and high-quality materials, resulting in a low failure rate, long service life, and saving users’ investment costs.

- Gypsum mill has the advantage of low mechanical and electrical consumption, less dust, and low Noise pollution, which is in line with modern environmental protection production and more energy-saving and environmental protection.

- The gypsum grinding machine adopts an electrical system for centralized control, with a high degree of automation, which can reduce manual costs and operating costs.

A Complete Gypsum Powder Production Line

- Vibrating Feeder: Ensure that the material transport evenly to the stone crusher;

- Stone Crusher: mainly used for the initial crushing of natural gypsum ore, generally requiring a discharge particle size of less than 30mm. Select different models of crushers based on the size and production requirements of gypsum;

- Belt Conveyor: used for conveying materials between different equipment;

- Powder Grinding Machine: used to grind the crushed gypsum into the required particle size. We can choose the model of the grinding machine based on the desired discharge particle size and output;

- Fluidized bed furnace: Fluidized bed furnace uses for calcining raw gypsum powder into calcined gypsum powder;

- Dust removal equipment: mainly used to remove smoke and dust generated in the process of calcining gypsum powder;

The primary equipment among them is the grinding equipment. If the selected grinding equipment is not good, it will fail to reach the fineness and production capacity of the ground materials, which will bring trouble to the production line process. Vertical mill, a new Raymond mill equipment with stable operation, environmental protection, and high production capacity, is a favorable assistant for industrial grinding.

Gypsum has a wide range of applications, and the effective recycling and utilization of gypsum processing are taken more seriously. With a customized grinding production line, Phosphogypsum can be ground to different degrees of thickness to meet the needs of further processing and production. JXSC Mine Machinery Factory provides all types of stone crushers and sand-making equipment, and all crushers accept customization. If there are any mining machines you need, warm welcome to inquire. Contact us online to get the factory price!