The Impact crusher is very popular among sand-making production lines and various stone-crushing plants. In a sand-making crushing line, Normally the jaw crusher is the primary crusher for coarse crushing, and the impact crusher is the secondary crusher for fine crushing. If the input material size is small, for example, under 150 mm, then the impact crusher will be a primary crusher in the sand production line. It is widely used in construction building materials, ore, railway, highway, energy, transportation, cement, mine, chemical industry, and other industries for medium crushing materials.

Application

The Impact crusher is used for material processing that often requires relocation operations such as metallurgy, the chemical industry, building materials, water, electricity, etc. Different requirements are required to adopt a variety of configuration forms. The impact crusher can process materials sizes below 100-500 mm with a high crushing ratio. After crushing, the material is cube particles. The discharge size is adjustable, and the crushing specifications are diversified.

Advantages Of Impact Crusher:

1. it is effective for impact crusher processing wet moisture material and prevents materials from blocking.

When the moisture content of the material is too large, the feed chute and impact plate can be equipped with a heating device to prevent the adhesion of the material, and there is no need to provide the bottom screen plate to avoid blockage.

2. The hardness of the application materials for the impact crusher is more extensive.

The impact crusher’s blow bar fix on the rotor with a mechanical clamping structure, which has large rotation inertia when rotating with the rotor. Compared to the hammer crusher (the hammerhead is hanging), the impact crusher’s rotor possesses a large amount of power for adapting to crush hard material, which also takes a low energy consumption at the same time.

3. It is convenient to adjust the discharge size of the impact crusher, and the adjustment range is wide.

There are many ways to adjust the impact crusher’s discharge port size, For example, we can adjust the speed of the rotor and adjust the gap between the impact plate and the grinding cavity. The gap size is adjusted by mechanical or hydraulic type, and we can adjust it through the machine operation button or remote control by the hydraulic system.

Maintenance

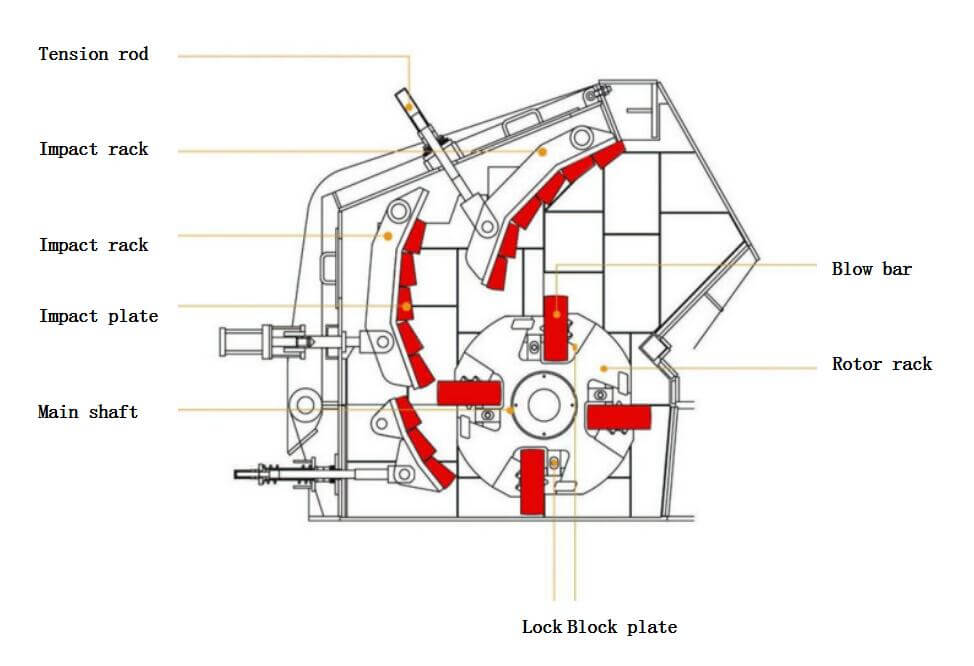

Working principle: The impact crusher adopts the impact energy principle to crush the material. Under driven by the motor, the impact crusher rotor rotates in the crushing cavity. After the material gets in, it will hit on the blow bar on the rotor. And strike back to the lining plate, under the effect of such a cycle crushing, the material discharge from the lower body, and then we can adjust the gap between the impact rack and the rotor to change the discharge size of the material.

Operation specifications: After the machine starts working and working normally, then we can feed the material into it. it is not allowed to feed big-size material or high hardness material into it. All the material should be crushed to pieces before stopping the machine. The machine should run positively. The vibration range of the machine does not exceed 0.2mm. After 8*24 hours of continuous operation, it should be stopped to rest.

FAQ

1. What is the influence on material if the rotor speed is slow or fast?

When the speed of the impact crusher is slow, the discharge speed is slow, the particle size is thicker, and the blow bar and the lining wear out less.

When the rotor speed is high, the fine particle increases, and the wear of the blow bar lining is accelerated. According to experience, when the low-hardness material like chopped cumbersome, the rotor speed is 50-60 meters/s. When it crushes limestone, the rotor speed is 30-40 meters/s, and the blow bar and lining are less worn.

2. What should we do if the discharge size is big?

- The blow bar might be damaged, which replaces the blow bar.

- The space between the blow bar and the impact plate is too large, which needs adjustment appropriately. Generally, the distance needs to be adjusted between 15mm-20mm.

- Excessive feeding particle size will also affect the discharge size

3. Why there are abnormal vibrations of the impact crusher?

- The feeding material size is too big, and the input material size needs to be adjusted.

- There exists uneven wear, it needs to replace the impact crusher’s blow bar.

- The rotor is out-off-balance, which need adjust.

- it may be caused by Improper basic treatment, which needs to check the tightening of the foot bolt.

4. Why is the bearing so hot?

- Excessive oil or oil unloading, checking the oil level when refueling.

- Bearing damage, we need to replace it in time

- The upper cover is too tight, it needs to adjust the bolt with appropriate tightness.

Daily maintenance of Impact crusher :

- Checking whether there are accumulated materials in the unloading port, if there are, clean them in time.

- We need to check the inner lining regularly, compression parts, and other worn parts. If there are spare parts damaged,it should be replaced in time. After changing the blow bar, check the balance.

- When there exist abnormal sounds or bearing temperature is over 70 degrees, Find the cause of the noise and high-temperature bearing, and repair it in time.

The above information described the application and maintenance of an impact crusher, Hope this information will help during the operation for sand or stone crushing production. Both the hammer crusher and impact crusher can crush coarse material to fine sand. Compare to a hammer crusher, relatively speaking the Impact crushers maintenance procedure is easier, because the hammer crusher wears out easily, and it is caused by its working principle and structure, etc. The VSI sand making machine is also widely known as a fine sand making machine, the capacity and cost are much higher than hammer crusher and impact crusher, the output requires a very fine size, so there is barely requires for maintenance. Besides these crusher machines, we can also provide other various crushers and complete sand-making plants, stone-crushing production lines, etc. Contact JXSC to get more information and get the factory price!